Summary

In the age of instant deliveries and razor-thin margins, warehousing isn’t just about storage — it’s the center of your supply chain. Every second counts, every error costs, and every optimization unlocks profit. But with so many different types of warehouses out there, how can you ensure your warehouse management system (WMS) is tailored to meet the unique needs of each storage model?

That’s where Stockelix Inventory Management System comes in, offering specialized solutions that adapt to various storage types, making your warehouse smarter, more efficient, and ultimately, more profitable.

Industries That Rely on Inventory Storage (Even If They Don’t Realize It)

You’d be surprised how many industries are secretly hoarding stuff like it’s Black Friday every day. From high-tech labs to glammed-up beauty brands, inventory isn’t just for warehouses and forklifts anymore. Whether it’s scalpels or sparkly sneakers, something’s sitting on a shelf somewhere. Let’s spill the tea on who’s storing what, and why they seriously care.

| Industry | What For | Why They Care |

| Retail & eCommerce | From fashion to furniture to fast-moving gadgets, retail lives and dies by how well inventory is managed, whether in fulfillment centers, store backrooms, or 3PL hubs. | Speedy delivery, accurate stock, smooth returns. |

| Manufacturing | Raw materials, spare parts, work-in-progress items — it’s like one big inventory ballet. | Downtime = disaster. Inventory keeps production moving. |

| Healthcare & Pharma | From medicine to medical devices, storage must meet tight compliance, climate control, and traceability requirements. | Patient safety, regulatory audits, and stock sensitivity. |

| Construction & Engineering | Think tools, equipment, safety gear, and materials, from nails to excavators. | Delays due to missing items = lost $$$ and angry clients. |

| Logistics & Supply Chain | This one’s obvious, they’re the pros at moving, holding, and tracking stuff. | They literally are the warehouse world. |

| Education & Research | Labs, classrooms, and IT departments all have stock (be it chemicals, lab gear, or laptops). | Budget control, safety, and keeping programs running. |

| IT & Software | Even the most digital companies need to track devices, accessories, software licenses, and support parts. | Smooth internal ops and secure digital asset handling. |

| Aerospace & Defense | Ultra-specific spare parts, sensitive gear, strict chain-of-custody — inventory here is next level. | Zero room for error. |

| Hospitality & Events | Linens, décor, AV gear, consumables — they store, prep, and rotate all of it. | Inventory supports smooth guest experiences and events. |

| Beauty & CPG | Product stock, packaging, raw ingredients — storage supports product launches and seasonal peaks. | Fast restocks and flawless presentation. |

Read Also What Is a Smart Inventory Management System and How Is It Different from Ordinary Solution?

Warehouse Types: From Distribution to Specialized Storage

Not all warehouses are created equal. For example, in logistics, the type of warehouse used can make or break operational efficiency, cost control, and customer satisfaction. Each type serves a different role in the supply chain, with its own unique goals, requirements, workflows, and equipment setups. Let’s have a deeper dive into some of the most common warehouse models and what makes them tick.

1. Storage Warehouses – Keeping Goods Safe and Accessible

These are the classic “store it ’til you need it” facilities. Storage warehouses are designed to hold inventory for long periods, often without frequent movement. You can typically find raw materials, spare parts, seasonal products, or surplus stock here. Because the turnover rate is low, the priority is maintaining a well-organized layout, safe storage conditions, and accurate inventory records. This is where inventory management software becomes especially valuable, as it helps monitor stock levels, reduce human error, and ensure everything is exactly where it should be. These warehouses often use shelving systems, pallet racks, and bins to keep everything in place and ready for when it’s needed.

Common struggles: Overflowing main warehouses, hard-to-locate items, manual stock checks.

2. Distribution Centers – Fast Fulfillment for Efficient Logistics

Unlike storage warehouses, distribution centers are high-velocity hubs where products arrive and leave quickly. Think of them as the middleman between manufacturers and customers, especially in retail and eCommerce. Their main function is to receive goods, sort them, and ship them out as fast as possible. Speed and accuracy are critical here, so you’ll see heavy use of automation, conveyor systems, and advanced picking strategies like zone or wave picking. Time is money in distribution centers, and every second saved in picking or packing mattersю

Common struggles: Slow order fulfillment, pick/pack mistakes, warehouse burnout.

Read Also How to Build an Ecommerce App and Live Happily Ever After

3. Commissioning Warehouses – Custom Assembly and Packaging

Also known as kitting or value-added service centers, these warehouses go beyond basic storage and fulfillment. They are responsible for customizing products before they are shipped – assembling kits, bundling items, applying promotional packaging, or including custom inserts. Retailers and brands use these facilities to prep products for specific campaigns or customer requests. It’s a more hands-on environment with specialized workstations, QA processes, and flexible workflows tailored to assembly tasks. To keep operations streamlined and error-free, many rely on inventory management software to track components, manage custom orders, and sync packaging with fulfillment schedules.

Common struggles: Inconsistent packaging, incorrect bundles, missed promo deadlines.

4. Specialty Warehouses – Compliance and Care in Storage

Specialty warehouses are built for products with specific storage needs. This includes temperature-controlled environments for perishables, secured areas for pharmaceuticals, bonded zones for international goods, or hazardous material facilities. These warehouses must follow strict regulatory standards, such as FDA, OSHA, or customs compliance, and often include features like humidity control, reinforced containment systems, or air filtration. They are the definition of niche logistics where attention to detail and compliance isn’t optional, it’s mandatory.

Common struggles: Spoiled inventory, failed audits, regulatory fines.

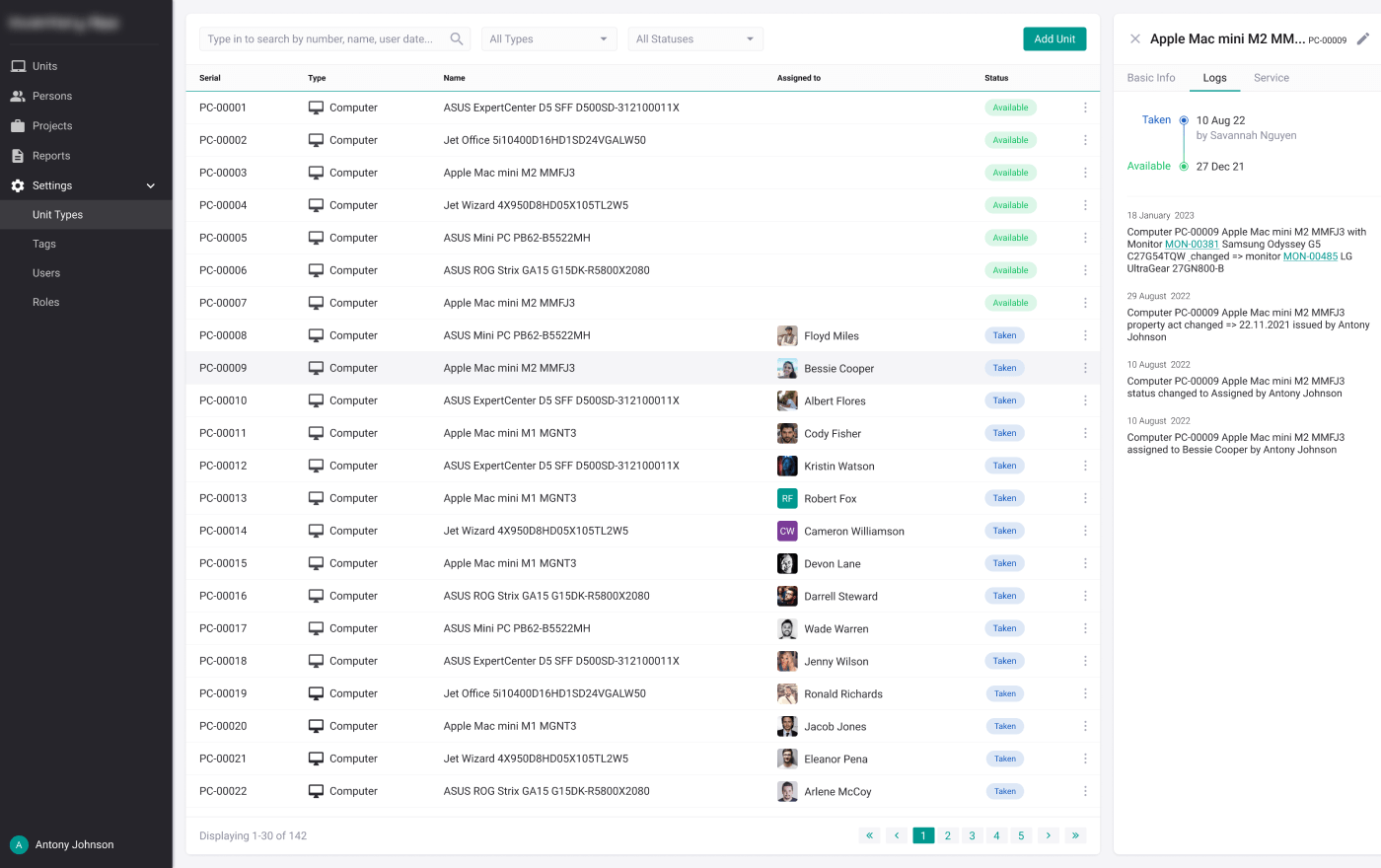

5. IT & Software Inventory Storage – Managing Assets Beyond Physical Goods

While traditional logistics focuses on physical products, IT and software companies also deal with inventory – just a different kind. You might not picture racks of hardware or forklifts rolling around when you think of IT & software companies, but inventory storage is very real in the IT world. It just looks a little different. Instead of bulk goods or seasonal stock, it’s all about high-value devices, mission-critical parts, and digital assets that keep systems running smoothly.

Think server components, networking gear, backup drives, and even high-value dev hardware (MacBooks, test devices, VR kits, etc.). These items often need secure, climate-controlled storage, meticulous asset tracking, and integration with digital asset management systems, which is why the warehouse and inventory management system development services are common to search for.

Common struggles: Lost or misplaced assets, outdated inventory logs, lack of integration with digital systems.

Read Also How IT Teams Can Manage Inventory Without Chaos (Or Losing Devices, Licenses, and Sanity)

Source: Warehouse and Inventory Management System

Some software vendors with on-premise solutions also maintain license dongles, specialized equipment, or even customer-specific hardware setups in warehousing environments. Plus, companies offering hardware/software packages (like IoT or embedded systems) often juggle both physical and digital inventories. Smart moves here include:

- RFID and barcode systems tied to IT asset management tools (ITAM),

- Temperature and dust control to protect sensitive electronics,

- Secure access zones for valuable devices,

- Audit trails for every movement.

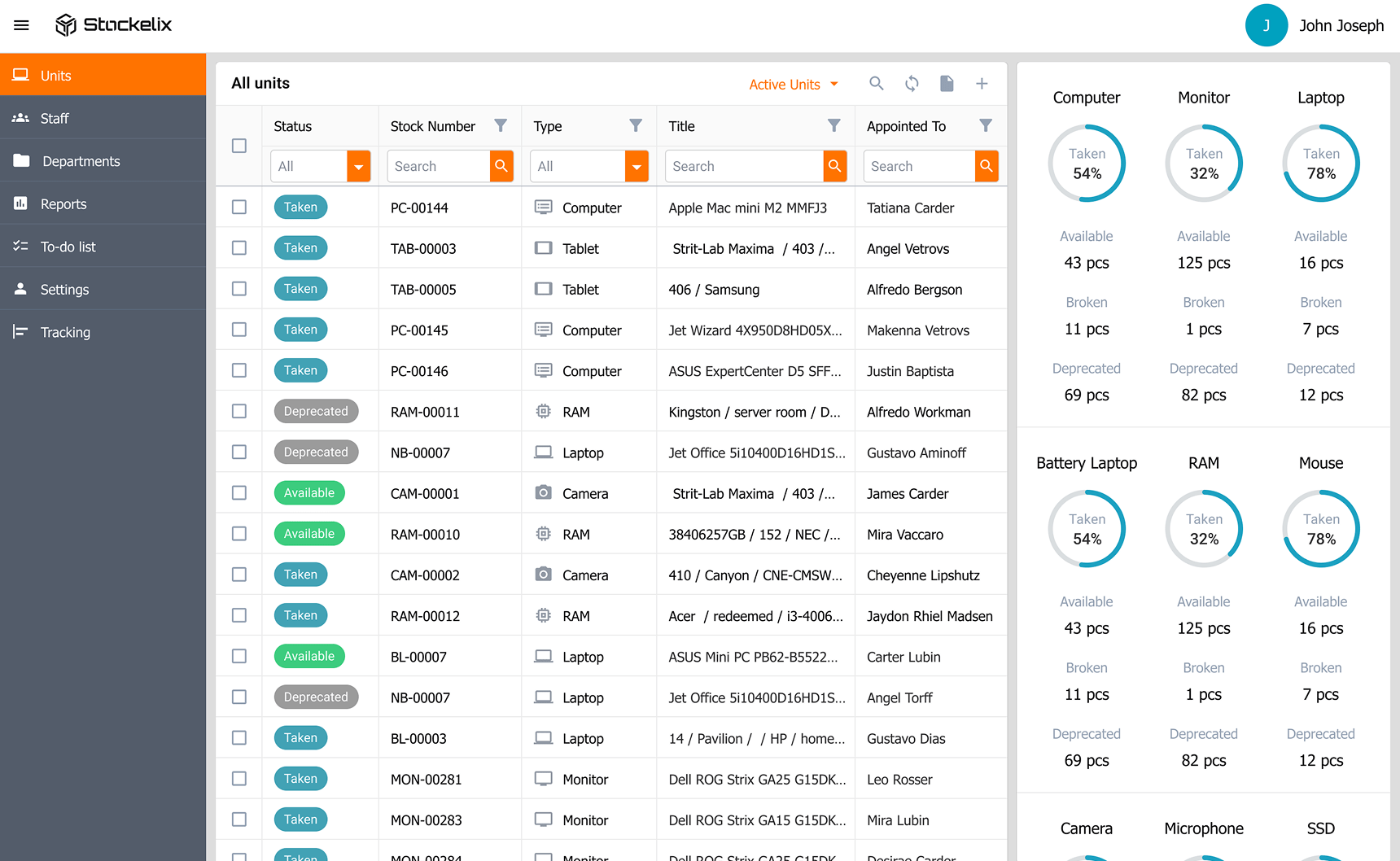

How Stockelix Adapts Across Industries

Imagine having one smart system that gives you full control and visibility over your inventory. Stockelix Inventory Management Application is designed exactly for this purpose. By replacing manual processes and disconnected tools with Stockelix, companies eliminate many of the root causes of warehouse pain points – resulting in faster processes, lower costs, and better decision-making.

Besides that, its adaptability makes it a valuable tool across various industries. Its customizable nature allows businesses in sectors such as healthcare, manufacturing, and retail to tailor the system to their specific inventory management needs. Whether it’s managing medical equipment, tracking manufacturing components, or overseeing retail stock, Stockelix provides a scalable solution that enhances operational efficiency.

Here’s how Stockelix features can be customized based on the industry needs:

Whether it’s high-SKU eCommerce inventory or bulk raw materials for production, Stockelix can let you define how each item is tracked — by serial number, lot, expiration date, or custom attributes like size, color, or vendor.

Without it, you risk sending wrong variants, having untraceable defects, and facing regulatory fines or recalls due to expired or untraceable stock.

Real-life scenario: A cosmetics eCommerce brand deals with thousands of SKUs, from lipsticks to serums, each in multiple shades and sizes. Without proper tracking, the warehouse kept sending the wrong shade of foundation, leading to angry customers and mounting returns. After implementing Stockelix, it is possible to start tracking by color and expiration date, which can lead to drops of returns.

Customizable for: retail, manufacturing, pharmaceuticals, food & beverage

Customize Stockelix Inventory Management Software to set up complex warehouse zoning, shelf and bin labeling, and location rules. Define temperature-controlled areas, vertical shelving, or high-turnover zones based on your operational logic.

Without it, teams waste time searching, hazardous materials can be misplaced, and high-turnover items cause bottlenecks during peak hours.

Real-life scenario: A frozen food distributor was manually sorting goods between regular and temperature-controlled storage. During the holiday rush, frozen turkeys were accidentally stored in dry zones and spoiled. With Stockelix, the company can zone the warehouse into cold, ambient, and fast-pick areas, so that every product is scanned into the right spot — no more misplaced poultry.

Customizable for: cold storage, hazardous materials, consumables.

Do you need to tailor role-based access for every team member — from warehouse operators and sales reps to clients and auditors? Stokelix helps to control what they see and what actions they can perform. Internal errors and data breaches go down, while trust goes up.

Without it, unauthorized users might delete orders or view confidential stock data. Auditors and clients face delays because access is manual or inconsistent.

Real-life scenario: A construction materials supplier had sales reps accidentally modifying inventory numbers in the system while looking up availability for clients. Once Stockelix is installed, the business is able to create strict access levels — sales could only view, not edit, while external auditors get temporary view-only access, speeding up audits.

Customizable for: 3PL providers, construction suppliers, logistics teams.

Companies that need to automate inventory top-ups based on reorder levels, expected demand, or shipping velocity can create client-specific rules, custom workflows, or even automate routine dispatches. With a custom inventory app, replenishment runs like clockwork — no panic reorders, no missed deliveries, and no frustrated customers.

Without it, stockouts happen too often, manual ordering eats up time, and clients may experience delays or missed shipments.

Real-life scenario: A clinic group was manually tracking when to reorder syringes, gloves, and testing kits. One Monday morning, a branch ran out of test kits — forcing appointment cancellations. With Stockelix, they can set up automatic replenishment rules based on usage velocity, which leads to stock being reordered before anyone even notices it’s low.

Customizable for: FMCG, consumables, clinics, subscription-based businesses.

With Stockelix, it is possible to enforce industry-specific checks during receiving, repackaging, or dispatch. Set up steps like weight verification, labeling inspection, documentation match, or quality scoring. Many businesses also want to enforce receiving, packing, and dispatch checks — from weight verification to documentation match, and it also can be easily dealt with.

Without it, wrong or damaged goods slip through. Compliance audits fail. Product recalls become costly and reputation-damaging.

Real-life scenario: A pharmaceutical distributor failed an audit because a mislabeled lot of medication was shipped without a documentation check. With Stockelix, they can implement a barcode-based verification process during dispatch. As a result, every order must pass a weight check and doc match step before it leaves — helping them stay audit-ready year-round.

Customizable for: pharmaceuticals, healthcare, food industry.

Do you want to manage and sync inventory across multiple locations? Stockelix can help you with that as well! Schedule internal transfers, consolidate shipping orders, or generate transport documents with a few clicks. Manage inventory across multiple sites and coordinate transfers or shipments.

Without it, teams lose visibility, overstock one warehouse, understock another, or duplicate orders. Customers wait longer and costs pile up.

Real-life scenario: A national retailer had one warehouse overflowing while another was constantly out of stock. Orders were getting delayed and customers were leaving bad reviews. Stockelix allows them to see real-time inventory across all locations, auto-transfer stock, and optimize deliveries.

Customizable for: national retailers, logistics hubs, field warehouses.

Building custom dashboards and reports showing warehouse performance, item turnover, space utilization, shipment delays, or stock anomalies (per client, location, or item group) is no longer an issue if you have Stockelix. You can create custom dashboards for performance, inventory trends, space use, and compliance.

Without it, you’re flying blind — relying on spreadsheets or gut feelings. It’s harder to forecast, spot issues, or justify decisions to stakeholders.

Real-life scenario: A compliance officer at a food distribution firm struggled to pull up incident data during inspections. With Stockelix dashboards, they can instantly show which batches had anomalies, where delays occurred, and how space was being used — turning their warehouse into a model of transparency during regulatory checks.

Customizable for: warehouse planners, CFOs, compliance officers.

Stockelix vs. Legacy System (Traditional Setup): What’s the Difference?

If making it simple and comparing Stockelix to a traditional inventory management setup, here’s the key differences that show just how much Stockelix Inventory Management App can improve your operations.

| Feature | Traditional Setup | With Stockelix |

| Inventory Tracking | Manual, error-prone | Real-time, accurate |

| Space Utilization | Disorganized, wasteful | Optimized with analytics |

| Order Fulfillment | Slow, inconsistent | Fast, automated |

| Data Visibility | Fragmented | Unified dashboard |

| System Integration | Disconnected silos | Seamless API connections |

| Customization | Limited | Fully configurable |

Conclusion: A Comprehensive Solution for Diverse Inventory Management Needs

Effective inventory management is crucial for the success of any organization, regardless of industry. Stockelix stands out as a versatile and efficient system that addresses the unique challenges of inventory tracking and management. By automating processes, enhancing accountability, and providing insightful analytics, Stockelix empowers businesses to optimize their operations and reduce inefficiencies.

Whether you are part of an IT department managing complex hardware and software assets or a business in another sector seeking to streamline your inventory processes, Stockelix offers a customizable solution designed to meet your specific needs. Embracing such a smart inventory management system not only improves current operations but also positions your organization for sustained growth and success in an increasingly competitive marketplace. So, if you are interested in enhancing your warehouse and inventory management processes, please contact us, and we will customize Stockelix based on your requirements.