Logistics in the pharmaceutical industry involves many people, facilities, and suppliers, which leads to the need for detailed coordination and scrupulous control. Pharma companies often deal with expensive and life-saving products, which increases the risks and the level of required responsibility. Medical supplies should be delivered to their destination quickly, safely, and under certain conditions such as a specific temperature range. Additionally, there may be an increased demand for certain medicines during periods of seasonal diseases. All these aspects lead to multiple challenges that a pharmaceutical company might face.

To avoid losing partners and increase their competitive advantage in the market, pharma companies need to work on improving the effectiveness of operations and revise outdated solutions. In this article, we’ll consider some of the main challenges of pharma logistics and look at software solutions that help to overcome them.

Human Resource Dependency

Despite significant progress in robotization in many industries, most logistics systems are still highly dependent on human oversight. Medications should be moved smoothly through the supply chain to ensure the safety of the product. All product movements should be documented. Packages barcodes should be scanned and saved into the database. Expiration dates should be checked before sending. All these tasks must be performed by well-trained personnel that treats the work with due responsibility. Another critical issue to keep in mind is the probability of theft. Many pharmaceuticals are valuable and have a high profit for relatively low volumes. Theft can lead to potentially dangerous drugs, such as radiopharmaceuticals, ending up in the wrong hands.

A custom ERP software solution with built-in Human Resources Management features can increase the control over the staff of a pharmaceutical company and automate dozens of tasks, starting with the applicant tracking and ending with employee offboarding. With such a system in your possession, you can efficiently find and target a specialist with the required set of skills. An HR system with the background check functionality can generate a pre-employment screening report that will contain such info as employment history, education, credit history, criminal background, and even drug screens. Additionally, you can quickly assess employees’ performance and track time spent on performing particular tasks.

Warehouse Management

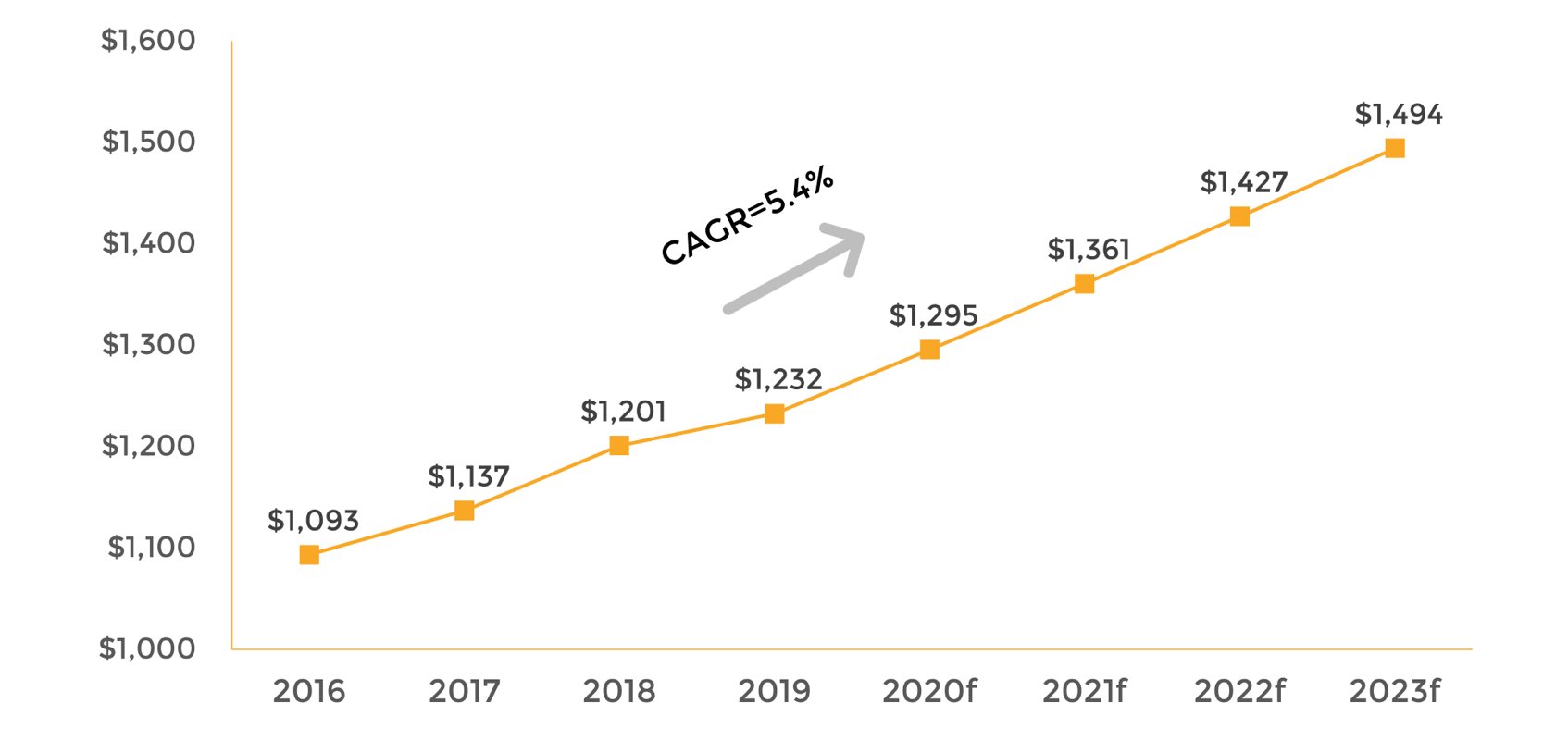

In 2019, the global pharmaceutical market reached $1,232 bn, and it is forecast to post a 5.4% compound annual growth rate at constant exchange rates through to 2023:

Image source: thepharmamarketer.com

Such an intensive growing market leads to an increase in sales volume, which means that every aspect of a pharmaceutical company that can guarantee an interrupted shipment of products can’t be underestimated. Warehouse management is one of the crucial factors that affect the overall productivity of a pharmaceutical company. The reason is that when working with medicines, you have to follow many rules and regulations. For example, the Current Good Manufacturing Practices (CGMPs) that refers to the regulations provided by the US Food and Drug Administration includes the following rules:

- Drugs must be stored to prevent contamination, and be positioned to allow for inspection and cleaning of the area;

- Each lot of drug products must be identified with a distinctive (and traceable) code, and the lot’s status must be identified (approved, quarantined, rejected);

- Written procedures must describe the distribution process for each drug. This includes procedures for recalls;

- Written procedures must describe the appropriate storage conditions for each drug.

As you can imagine, off-the-shelf warehouse software designed for an average customer most probably won’t include all the features required by a pharmaceutical company. In this case, there’s the need either for a software tool initially designed for the pharma industry or a custom-made solution built according to a specific company’s needs.

With a custom-made supply chain management system, you can effortlessly track items’ movement in and out of the warehouse and monitor their further delivery to customers. According to the regulations specific to your country or your preferences, you can use, for example, RFID tags or QR codes for that purpose. Such an approach will free you from the need to use extensive documentation. Instead, you can rely on a system allowing your employees to use readers or barcode scanners for scanning items in a warehouse. This data will be automatically saved in the database and can be easily accessed anytime in an easy-to-read form. All new items can be scanned after their arrival and during all the movements across different warehouse areas. With the rise of biologics, pharma companies have to follow new rules regarding product safety, especially proper handling and storage in refrigerated conditions. Warehouse management software can enable the temperature monitoring of cold storage systems and other inventory control processes necessary for specific medications.

Read Also How Advanced Warehousing Can Help Your Business Overcome Long-term Crisis

Transportation Issues

Most pharmaceutical products need to be stored at a particular temperature while they’re stored in the warehouse. Unfortunately, since the transportation process may take quite a long time, providing and controlling medications’ temperature conditions through the transportation period from origin to the destination can be a pretty tricky task. Different drugs have different temperature requirements, and refrigerated trucks may have several temperature areas, which don’t make things easier. If the temperature in which the drugs are stored is not correct, they can degenerate and become useless for the patients taking them.

Fortunately, custom-made tracking software allows you not only to see where exactly your products are at a given moment but also to check whether the required temperature is maintained. IoT-devices can efficiently monitor important indicators and send them to the cloud. With IoT monitoring systems, you can collect and process this data to control temperature and humidity in real-time. This data can be gathered during the whole cycle of shipment and, along with the info on each shipment’s location, provide timely and reliable info. Analyzing received indicators, you can quickly define if the temperature exceeds acceptable limits.

Shortage Avoidance

One of the essential tasks that a pharmaceutical company has to deal with is making sure that the supply of drugs meets the demand of pharmacies, hospitals, and patients. The probability of theft or damage during transportation makes this a constant challenge that can’t be ignored. Dozens of regulations that a pharmaceutical company should follow can make the task even more difficult. Probably, the easiest way of avoiding a shortage of medications is to keep some backup at your warehouses and have secondary sources of necessary resources. Such an approach may have its advantages, but there are some more effective ways of keeping your supplies at the needed level.

Every pharmaceutical company generates a vast amount of data that can be used for generating insights to optimize the circulation of medicines between the company and its customers. Machine learning is an application of artificial intelligence (AI) that can help pharma companies to manage accumulated data to optimize planning, increase sales, and improve customer service. Such features of AI-driven systems as predictive analytics allow pharma companies to access tools for aggregating and analyzing data from dozens of different sources. Such an approach helps to predict possible hurdles or increased demand for medicines associated, for example, with seasonal illnesses hurdles. It allows allocating required resources in advance and avoiding clients’ dissatisfaction with the quality of provided services.

Conclusions

The pharmaceutical industry is rapidly growing, which increases the pressure on pharma companies struggling to deliver sensitive medicines on time and in compliance with dozens of requirements. The need to maintain the required temperature during storage and transportation, a complicated procedure of disposal of expired medicines, probability of theft, and many other small and not-so-small aspects of the industry make the need for specialized software solutions obvious. Fortunately, modern technologies such as IoT and AI can guarantee significant benefits for a pharmaceutical company that decides to adopt a custom-made logistics system.

Contact us to learn more about software solutions that can improve the efficiency of your pharmaceutical company.