Business data is constantly changing. It moves from one company department to the other, acquires new indicators, visualizes in the form of graphs and reports, and so on. To keep up with these constant changes, numerous software solutions were introduced. Electronic Data Interchange (EDI) and Enterprise Resource Planning (ERP) are vital tools for businesses seeking to optimize their operations and enhance collaboration across their supply chains. Today, we’ll consider their major differences and examine the benefits one can reap from adopting these technologies.

What’s an ERP System?

ERP, or Enterprise Resource Planning systems, are powerful tools that integrate various aspects of a business, enabling seamless information flow, enhanced collaboration, and improved decision-making. Let’s explore ERP’s main features that empower businesses to thrive.

Centralized Data Management. ERP acts as a centralized repository, consolidating data from different business departments and organizational functions. It provides real-time access to critical information, enabling employees to make informed decisions based on accurate, up-to-date data.

Process Automation. ERP solutions can help automate routine and repetitive tasks, eliminating manual efforts and reducing the chances of errors. By automating processes such as order management, inventory control, and financial reporting, ERP enables businesses to streamline their operations and increase productivity.

Read Also Hyperautomation: A Blessing In Disguise for Modern Businesses

Integrated Modules. ERP systems typically consist of integrated modules that cover various functional areas, including finance, human resources, supply chain, customer relationship management, and more. These modules work together seamlessly, facilitating cross-departmental collaboration and ensuring data consistency throughout the organization. You can leverage this feature and build an ERP solution that fits your current needs. As your business grows, you can cooperate with a software developer to integrate additional modules into your ERP app.

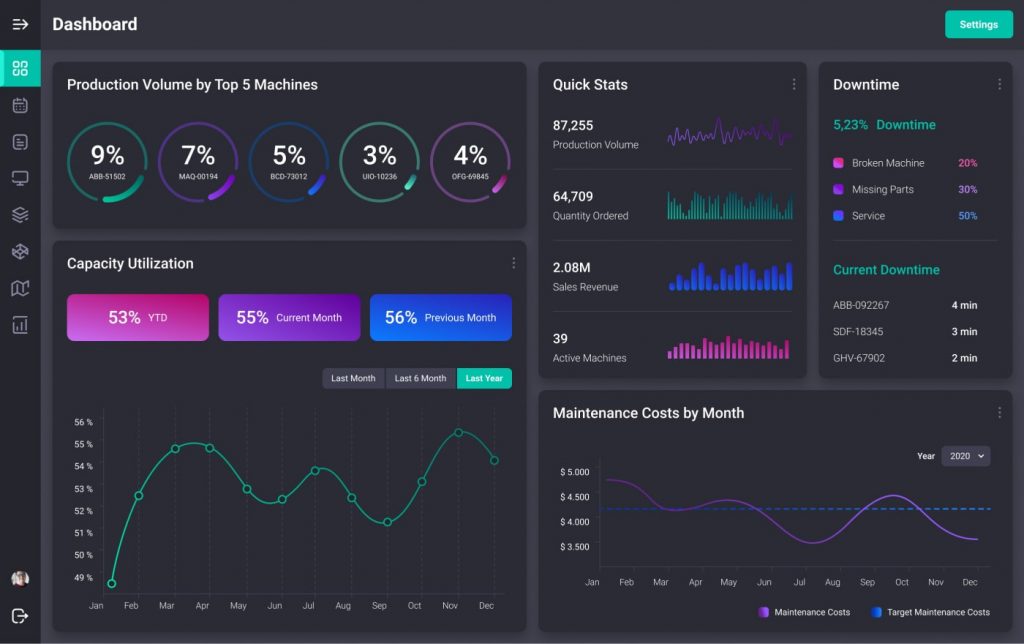

Real-time Reporting and Analytics. ERP provides powerful reporting and analytics capabilities, allowing companies to gain valuable insights into their operations. With customizable dashboards, graphical representations, and ad-hoc reporting, ERP empowers decision-makers to monitor key performance indicators, identify trends, and make data-driven decisions swiftly:

Source: Advanced ERP Software for Manufacturing Company

Enhanced Communication and Collaboration. ERP fosters improved communication and collaboration across different business departments and geographies. By providing a centralized platform for sharing information and facilitating cooperation, ERP breaks down silos and promotes efficient teamwork, leading to increased productivity and innovation.

Scalability and Flexibility. ERP systems are designed to accommodate the evolving needs of growing businesses. They offer scalability, allowing organizations to add new functionalities and users as their requirements expand. ERP’s flexibility enables customization and configuration to align with specific business processes, ensuring the system adapts to unique organizational needs.

What is EDI?

Now, let’s deal with EDI or Electronic Data Interchange. This technology facilitates seamless and standardized communication between trading partners, eliminating manual processes and enabling rapid exchange of critical business information. It appeared in the 1980s to replace such obsolete means of communication as fax. While ERP is a powerful tool for increasing productivity, EDI is a method of exchanging business information, such as invoices, shipping status statements, purchase orders, etc.

EDI can work as a standalone technology for exchanging business data. However, it can be integrated into the ERP system to enrich its functionality. The modular nature of the ERP software we mentioned earlier makes such adjustments effortlessly. Plus, robust exchange of real-time business data can be beneficial when many moving parts are involved, for example, in supply chain management. Let’s consider the main features of using EDI in business.

Automated Data Exchange. EDI replaces traditional paper-based methods with digital formats, allowing for the automatic exchange of business documents.

Standardization and Compliance. EDI adheres to standardized formats, such as ANSI X12 (for businesses from the US and North America) and UN/EDIFACT (for businesses from Europe and Asia), ensuring consistency and compatibility across different systems and trading partners. It simplifies data interpretation and ensures efficient collaboration.

Increased Efficiency and Cost Savings. The automation and elimination of manual processes offered by EDI result in significant time and cost savings for businesses. By streamlining workflows, reducing data entry efforts, and accelerating information exchange, businesses can allocate resources more effectively and achieve improved operational efficiency.

Enhanced Accuracy and Data Integrity. EDI minimizes the risk of errors associated with manual data entry and transcription. By enabling direct business data transmission between systems, it ensures its integrity and reduces the likelihood of discrepancies or misinterpretation.

Read Also: ERP and MRP: Going for the Suitable Choice One Step at a Time

Faster Transaction Processing. With real-time data transmission, businesses can accelerate order processing, shipping, and invoicing, improving customer satisfaction and enhancing supply chain management.

Making ERP And EDI Work Together

Since modern ERP software developers follow a modular approach and the functionality of such apps is consistent with what EDIs have to offer, you can always combine them. Such integration provides a myriad of benefits, changing the way businesses operate and collaborate with their suppliers and customers, including the following:

- Enhanced operational efficiency thanks to automation that streamlines order processing, invoice generation, and inventory management. By minimizing manual interventions, businesses can use their resources more efficiently;

- Increased transparency can be achieved by instant access to accurate information on orders, shipments, and inventory levels, for example, which leads to better decision-making;

- Reduced costs. ERP with integrated EDI can eliminate the need to handle paper-based transactions manually and perform repetitive data entry operations. EDI automates these processes, reducing labor costs;

- Error reduction and compliance. EDI integration ensures the accuracy and integrity of business data by eliminating manual input, thereby reducing the likelihood of errors. EDI adheres to industry standards and ensures compliance with various regulations.

If you can’t wait to integrate EDI into your ERP solution, you should always start by evaluating business requirements. Assess your business needs and goals for EDI integration. Identify the transactions to be exchanged. Determine the required scope and scale of integration, considering factors like trading partner relationships and transaction volumes. Also, check the software your business company works with. EDI is not a new technology. Therefore, there’s always a chance that you have been using such a solution for a considerable time. Integrating legacy software into a modern cloud-based ERP system can cause additional challenges and costs.

You should choose a compatible EDI solution and integration type. EDI app must align with your ERP system and trading partner requirements. Ensure that the solution supports the necessary document formats, communication protocols, and EDI standards (e.g., ANSI X12 or EDIFACT). Speaking of integration types, there are some examples:

- Direct integration entails establishing a direct online connection between your ERP system and trading partners through a dedicated protocol. This connection enables the secure exchange of electronic documents. It is essential for both you and your trading partner to utilize the same communication method or protocol to facilitate seamless communication;

- Indirect integration is a more scalable approach that enables multiple connections with other partners.It involves the electronic exchange of documents through a Value-Added Network (VAN) or a Managed Service EDI provider;

- Hybrid integration can be a decent choice if you exchange large volumes of documents with a couple of business partners and also have multiple smaller partners requiring less documentation traffic. Here, you can mix two previous integration approaches;

Since EDI is all about exchanging business data, make sure you’ve established trading partner connections. Communicate with your business partners to exchange necessary information such as EDI addresses, document specifications, and communication protocols.

Configure and test ERP integration with your IT team and EDI solution provider. This process involves mapping data fields between the ERP system and the EDI solution to ensure accurate data exchange. Conduct comprehensive testing to validate end-to-end transaction flows and address potential issues before going live.

When everything’s up and running, your primary task is to monitor and maintain the system continuously. Make sure no anomalies or errors will escape your eye. Regularly maintain and update the integration to accommodate changes in trading partner requirements, industry standards, or system upgrades. Also, continuously evaluate the integration’s performance and effectiveness to identify improvement areas.

Conclusions

The primary purpose of both ERP and EDI is to make your business more efficient and transparent. The ways they help you to achieve this goal differ. ERP focuses on how you handle your business data, and EDI exchanges it with stakeholders securely and as quickly as possible. The best part is that you can take advantage of using them both by integrating EDI into your ERP solution.

Contact us if you’re looking for a reliable partner to implement your ERP system or expand the capabilities of the one you already have.