The emergence of the Internet of Things (IoT) has changed our perception about technologies and their implementation. Literally every sphere and even our everyday life underwent significant transformations due to digital disruption. Manufacturing industry managed to digitize and establish dozens of processes, modify business models, and boost overall efficiency. This breakthrough has become possible due to the implementation of Industrial Internet of Things (IIoT), which is now used in almost all workflows of the manufacturing process. In this article we discuss the Industrial Internet of Things, speak about its implementation in the manufacturing industry, and define the benefits and risks.

What is Industrial IoT(IIoT) and How It Differs from IoT?

Industrial IoT or IIoT is a subset of a well-known IoT we use in our everyday life. Unlike traditional IoT which is normally used by ordinary consumers to enhance quality of life and for fun, industrial IoT is used at industrial level. We can say that IIoT is a system of computer networks linked together and connected with industrial facilities that are equipped with sensors for gathering and exchanging data, with the possibility of remote control and automated functioning. The system allows the industrial equipment to function without human intervention.

The description of Industrial IoT is pretty similar to the description of IoT. Common technologies are used in both cases, and the principles of work are also alike. But nevertheless, the differences exist and they are in the additional design parameters which industrial IoT performs. They are the following:

- Security

You couldn’t agree more, that security aspect is a critical point for Internet of Things (IoT), but if we speak about the industrial scale,Industrial Internet of Things (IIoT) requires stronger measures. Even a minor malfunction during the manufacturing process may lead to tremendous money losses and influence the economic activity of a large number of people. It especially concerns high volume manufacturing processes involving an enormous amount of workflows and people. Taking into consideration this fact, there arises the strong necessity to apply more serious security measures to avoid undesirable consequences. - Functional Compatibility

There is a wide number of different types of solutions besides industrial IoT a manufacturing company may use. Therefore, it’s important for all the elements of this environment to interact with each other seamlessly. IIoT should integrate with an ERP system that is used in a company, and support different protocols and data sets. - Scalability

When we speak about industrial scale, we should take into account the amount and variety of robots, sensors and other devices involved in the manufacturing process. In comparison with traditional IoT, industrial IoT deals with large scale networks and supports the enormous amount of sensors and devices underused in the manufacturing process.

- Reliability

Conditions under which machinery equipment functions significantly differ from the conditions which we have in our homes for instance. The equipment operates in different environments: in extremely high or low temperatures, and under dangerous conditions from day to day over the years. Therefore in order to avoid any malfunctions that may lead to expensive repairs or even replacement of some equipment, IIoT must be reliable and operate flawlessly. - High Level of Accuracy

Manufacturing process is established in a way that all the equipment operates precisely and coherently. Industrial Internet of Things (IIoT) systems detect even minor deviations and take prompt measures which allows to avoid downtimes and revenue losses.

Read Also How IoT Simplifies Our Life and in Which Spheres It is Used

Benefits of Industrial IoT

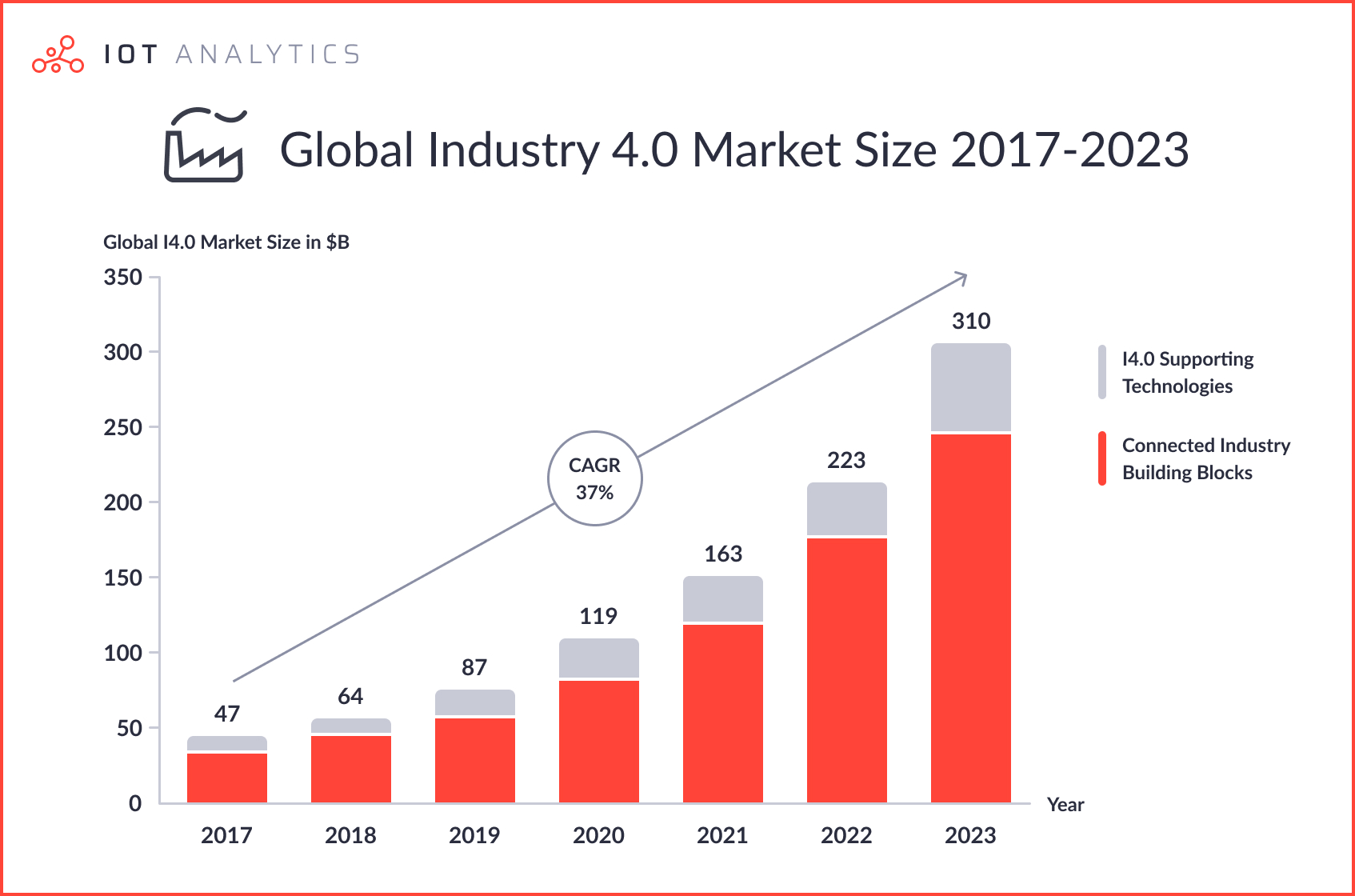

Nowadays many companies offer bespoke software development services, and IIoT is used on many industrial enterprises. The number of companies that have adopted IIoT solutions is constantly growing. This fact proves the reasonableness and efficiency of its usage. Let’s take a look at the graph below:

Image Source: IoT-analytics.com

The graph reflects the forecast of Industrial IoT market growth. According to it, the global IIoT market will reach 310 billion dollars by 2023.

Manufacturing companies are ready to invest in IIoT implementation due to the extensive list of benefits they will get in return. Below are the main beneficial points of Industrial IoT that will help to make decision whether to apply the IIoT solution in your business or not:

- Predictive Maintenance

This point can be compared with human health. In any case it is much more efficient and rational to prevent a disease than to treat it at the advanced stages. That is also true with machinery equipment. Due to the sensors installed on the equipment, manufacturers can get valid data related to its condition. Provided data allows to evaluate the state of the equipment and detect malfunctions that need fixing. Such an approach helps to prolong the equipment lifetime, significantly decrease risks of downtimes, and lower risks of accidents that may threaten human life and exert a negative effect on the environment. - Predictive Quality

Data collected by sensors helps evaluate the overall conditions in which the equipment is functioning. Along with human observations, such an approach becomes effective for predictive quality analytics which helps to optimize the quality of end products. Owing to Industrial Internet of Things implementation, manufacturers are able to create predictive quality models which entails product quality improvement. It decreases the possibility of defects and therefore products return. - Asset Tracking

Asset conditions monitoring allows manufacturers to monitor the condition of the machinery equipment in real-time mode. Such indicators as temperature, humidity, and vibrations show if the equipment operates in an optimal manner, and provide guarantee that the asset resources are fully utilized. - Remote Monitoring

The possibility of remote monitoring provided by IIoT helps operators perform efficient control over the equipment during its functioning. In case of any malfunctions they receive signals and are able to take necessary measures immediately. Therefore the operators will always be aware of the machinery condition. - Overall Expenses Reduction

This benefit includes all the points listed above. Implementation of industrial IoT solutions allows to perform control over the possible risks and thus the financial component of manufacturing business. Such risks as downtimes, inefficient resources distribution, untimely equipment maintenance etc. — can be significantly reduced or even totally avoided with the help of IIoT sensors and devices.

Conclusions

Manufacturing process is a set of complex workflows that require precision and accuracy. If you implement Industrial Internet of Things solutions into your manufacturing business you may be sure that the entire process works like clockwork, and the risk of various unexpected issues connected with machinery condition is minimized.

If you want to transform your business with contemporary solutions and currently looking for development services for manufacturing, please contact us, our team will assist you with pleasure.