The future of electricity production is shifting in favor of renewable sources. Geothermal energy is playing an increasingly important role in this global movement. It’s clean, sustainable, and can be extracted from the Earth’s surface, making it an attractive option for meeting global demands. It also has the potential to be developed in more remote locations that previously lacked access to such energy sources, helping to bridge the worldwide gap between extraction and use.

Software development, in its turn, is becoming increasingly important in this field. Innovative software solutions are being developed to improve the efficiency of energy production, ensure safety, and reduce associated costs. Today, we’ll consider the most critical trends and look at how software development can help in this field.

What’s Geothermal Energy and How to Use It

First, let’s talk quickly about how you gather and use such energy. As the name suggests, here we deal with heat hidden in the depths of the Earth. To be precise, in its very core. Long story short, the Earth’s core is pretty hot. The surface is thousands of degrees cooler, leading to continuous thermal energy conduction. The next step is to use these natural sources somehow.

Water heated this way has been used for ages but the history of using it for producing electricity is much humbler. However, the first case of producing electricity with geothermal heat took place over a hundred years ago. In 1904, the first power plant using this principle was built in Italy. It used dry steam going from the ground fractures to drive a turbine. It is the oldest and probably the most natural way of turning geothermal potential into electricity.

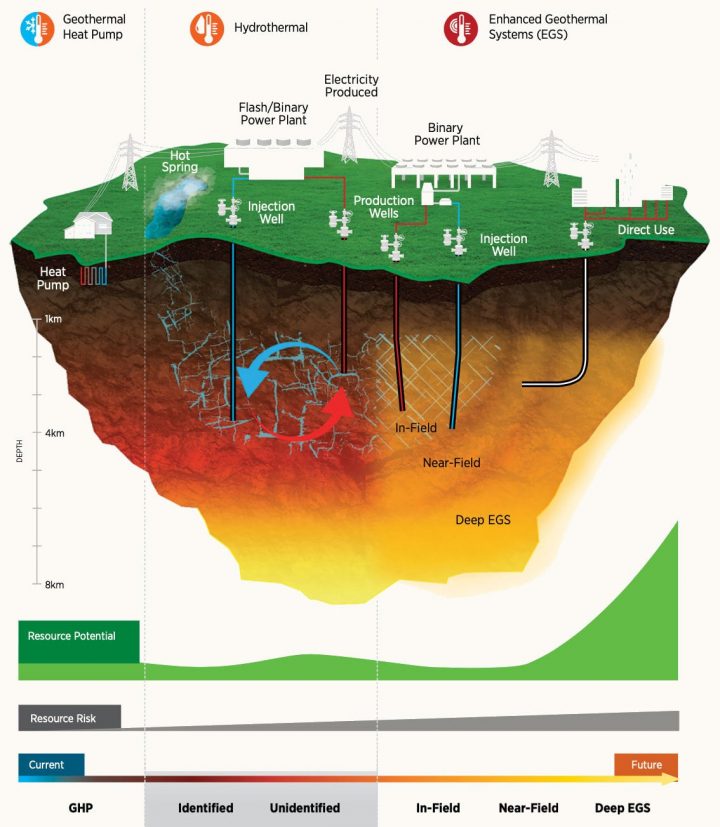

Years of development have led to more advanced technologies. Flash plants, for example, mix high-pressure water from underground with cooler low-pressure water. The steam created this way turns the turbine to produce electricity. Also, there are binary plants. Here, hot water goes through another fluid with a lower boiling point. This second fluid, in turn, vapors and drives the turbine.

Source: Yale Environment 360

Currently, the US holds the place of the largest power development country in this field. But there’s another country that is primarily associated with it. Iceland is the best place to harvest powers produced by the Earth’s core. They have more than 20 active volcanoes and 600+ hot springs. Investments in geothermal technologies development allowed the production of more than a quarter of energy this way.

Read Also Top 7 Life-Changing Trends in Energy & Utilities Industry

The trend looks set to continue since this approach has many advantages. First, it’s environmentally friendly, especially compared to such options as burning coal. The source itself is renewable. There’s no reason for the Earth’s core to suddenly cool down. It means we can rely on geothermal energy development and Energy and Utilities software for as long as our planet exists.

Unlike in the case of electricity gathered thanks to the sun or wind, everything’s pretty much predictable here. After all, the chances that some underground clouds will appear and prevent the Earth’s core from producing heat are meager. Also, it’s easier to calculate how much electricity you’ll get since the source is not as unpredictable as the wind, for example. Plus, the field shows surprisingly vast development possibilities starting with introducing new materials and ending with using cutting-edge software solutions.

Trends to Expect From Geothermal Energy

Holistic Approach

Geothermal sources may look like a risk-free investment field since all you have to do is to drill some holes in the ground and use what mother nature has to offer. However, drilling and subsequent surface and subsurface infrastructure building require tons of effort. Therefore, there’s a need for accurate assessments regarding the economic feasibility of a specific project and its future development. Underground fluids, for example, can be converted into heat or power. These two purposes of using geothermal sources imply different approaches and getting different outcomes.

That’s where a holistic approach comes into play. With the help of analytical software, engineers can bring together their expectations, the actual state of subsurface conditions, and the predictive design of future surface systems. Such software can use the info regarding the resource’s capacity and build a model that helps to understand its potential. Here, the costs and risks of drilling and creating a power plant can be compared to potential thermal output.

Using ERP software in geothermal energy can help to manage and optimize business processes, resulting in greater efficiency and cost savings. ERP systems provide a holistic business view by connecting various departments through a single platform. It makes it easier for companies to access data quickly, make informed decisions, and reduce the time to complete everyday tasks. Such apps help automate day-to-day tasks that are not always related to the energy itself but are still significant. Here, we mean invoicing, inventory tracking, and financial reporting, where automation can lead to better accuracy and faster turnaround times. Furthermore, using predictive analytics, ERP software can accurately forecast future trends and demand, allowing geothermal energy companies to make better-informed decisions.

Enhanced Geothermal Systems (EGS)

Sometimes, what’s under the surface is insufficient to produce electricity efficiently. Lack of the required amount of fluids may become a significant problem. EGS can be somewhat helpful in these cases. Once again, software development can become useful. Solutions specifically designed for companies in this industry can be used for modeling. This approach saves tons of money compared to a series of on-the-field attempts allowing engineers to assess what turbomachinery design will fit the specific conditions.

Subsequent use of monitoring software helps to bring together data received from installed sensors and AI algorithms to optimize the power output. Last but not least, there’s always room for automation. Robotic drilling systems and reliable software to control them enable remote drilling. Here, you can rely on a team of experienced engineers working from the control room and decrease the number of required people on-field.

Use of Advanced Materials

Described kind of energy has been in use for centuries which doesn’t mean it stalled in development and reached its final form. The materials used in the process require as much attention as modeling software. High temperatures and pressures plus risk of corrosion are the factors that do not allow the use of the same materials as the pioneers of the industry more than a century ago.

Software systems can help consider the structure of the Earth’s crust at a specific point. With this info, you can use drilling techniques to minimize the contact between the casing and the borehole. Such an approach helps to ensure well integrity. However, to reduce the risk of corrosion and prolong the life of casings and pipes and save them from the destructive nature of the brine chemistry, modern companies rely on non-metallic composite materials.

Additive Manufacturing

The concept of additive manufacturing, commonly known as 3D printing, describes a manufacturing process where materials are arranged in layers to form precise geometric shapes. This approach makes it possible to use novel materials to produce components with complex geometries, which could not be accomplished using other traditional manufacturing procedures. Modern software solutions help companies adopt efficient waste management techniques to make additive manufacturing more efficient.

Read Also How to Build an Efficient Waste Management Application

By combining 3D printing and conventional machining, businesses can manufacture components that can endure temperatures of up to 450°F and 10,000 PSI which is a lot. This technology can produce drilling systems, drill bits, heat exchangers, and many other components. We can anticipate that additive manufacturing, in conjunction with non-metallic materials, will revolutionize enhanced geothermal systems in the future.

Conclusions

Using geothermal energy may sound like an industry with no room for adopting cutting-edge technologies. Although this specific technology isn’t at the forefront of science, the area for development is quite extensive. New materials, robotics, AI software solutions, and IoT are only a few examples of how modern tech can increase the efficiency of energy production and utilization efficiency.

Contact us if you’re interested in adopting a reliable, cutting-edge software solution to boost your business.