The diversity of processes involved in the manufacturing business requires implementing the mechanism that constantly monitors dozens of various operations. Without specialized software solutions, it’s hard to handle the production and transportation of raw materials, lifecycle management, workforce monitoring, order management, asset management, quality control, delivery of the final product, and many other day-to-day activities.

Luckily, an enterprise resource planning (ERP) system designed according to your business’s needs might be an effective solution for managing the entire process of manufacturing, eliminating unwanted complexities, and increasing your sales and profitability. In this article, we’ll consider how custom ERP solutions can help automate various business processes of a manufacturing company and what benefits they can bring.

How ERP Solutions Can Help Your Manufacturing Business

ERP systems can collect all the data that each department of your company generates, store it securely, and use it to help you meet your business goals and satisfy your customers’ expectations. According to the size of your manufacturing company or peculiarities of your business, your ERP system can include various modules, each with its specific set of features. For example, you may want to receive real-time information about your trucks’ location and the condition of the cargo. Or you may want to estimate the efficiency of your employees. Want to know how effective your business processes are and how close you are to achieving your goals? Not a problem. Manufacturing ERP solutions can help you to deal with all these and many other tasks.

Any experienced development company has a plethora of integrated ERP modules to offer. Among them, you can find:

- Reporting Module

- Customers and Orders Management Tools

- Workload Management Tools

- Manufacturing Module

- Financial Module

- Supply Chain Management Module

- Time Tracking System

- Client Database CRM Module

- Projects Dashboards

- Invoices Database

- Calendar Module

- Payroll Module

As you can see, such software solutions for manufacturing can cover the needs of your company’s any department. The best part about dealing with a custom software developer is that there’s no need to pay for the ERP system overloaded with unnecessary functionality. Following your own business vision, you can invest in creating a lightweight ERP solution that will solve a particular issue and then increase its functionality by adding new modules as your business grows and enters new markets.

When It’s Time for Manufacturing Company to Adopt An ERP System

If you’re asking yourself if ERP system development is worth your time and money, there are several factors to consider. You should probably start thinking about adopting an ERP system if you can’t effectively collect and process your data. If you are sure that you and your employees work as hard as possible, but your manufacturing company still can’t reach its goals, maybe the reason is that you can’t estimate the effectiveness of used business processes due to a lack of comprehensive information. In this case, access to real-time data and interactive reports that an ERP system can generate every week, month, or year, depending on your preferences, can help you develop some valuable insights and make important decisions.

If you want to make sure that your company works like a well-coordinated mechanism, you should ensure a barrier-free flow of information between departments. The use of various disconnected systems that don’t communicate with each other may cause delays in work and decrease customer satisfaction. Your custom manufacturing ERP system can provide your employees with easy access to all required information along with some reliable communication tools.

If your company is growing too fast and your existing system can’t cover its needs, most probably, it’s time to look for a more flexible and scalable system.

Finally, if you need to reduce costs but don’t know where to start, you can think of an ERP system that can be the exact tool for reducing manual and time-consuming processes by automated, streamlined processes.

Main Benefits of Adopting a Custom ERP Solution

First of all, an ERP system for manufacturing business can be an excellent choice if you seek automation. Routine activities, such as work with documentation and manual data entry, can significantly reduce your team’s overall performance if you don’t take them seriously. Thanks to the ERP system, you can reduce your dependency on manual processes, which will lead to an acceleration in production, minimized errors, and improved profitability.

ERP systems enable access to data of various types gathered across your company’s different departments via a single platform. Every bit of information from invoices to delivery routes can be stored and analyzed using the ERP platform. Any employee that has required access rights can view or edit available records in a few clicks.

Built-in analytics tools can be irreplaceable for developing insights from data generated during day-to-day activities.

Real-time data analysis is the ERP system feature that allows responding to changing market conditions quicker. You will be able to make data-driven business decisions thanks to regular reports that reflect varied market demands. Detailed insights can give your managers a 360-degree view which can be pretty handy if you want to reduce forecasting errors.

Accurate production forecasts, enhanced control over your inventory, automated processes, and constant control over your logistics can improve on-time delivery and improve customer satisfaction.

ERP Modules Applicable to Manufacturing Sphere

It’s hard to cover all possible features that a custom ERP system can provide since every company has its characteristics and follows its unique approach. Nonetheless, there are some features required by most manufacturing organizations. In this chapter, we’ll take a look at some ERP modules that can help you improve your business processes.

GPS Vehicle Tracking System

![]() Screenshot from: GPS Vehicle Tracking System Case Study

Screenshot from: GPS Vehicle Tracking System Case Study

GPS tracking modules for an ERP system can be suitable for any company that uses movable machinery. The use of such software solutions allows simplifying vehicles’ movements and increasing the efficiency of routing and dispatching of vehicles. A relatively simple combination of a GPS tracker and mobile app allows monitoring each piece of your equipment’s exact location, whether it’s left on a site or is still on the territory. Features that GPS tracking provides help to reduce paperwork and save fuel. Tracking systems can be integrated with interactive mapping software most commonly used in your country, such as Google Maps, Yandex Maps, or OpenStreet Map, for example. According to your requirements, GPS tracking systems can provide such additional features as engine diagnostics reporting, route optimization, real-time GPS tracking, accident detection system, fuel consumption monitoring, and more.

Ensuring Appropriate Delivery Conditions

If you work with sensitive or fragile materials, the use of Internet of Things (IoT) devices installed on the vehicles can enable real-time tracking of important indicators. For example, your ERP system can collect and process data on temperature and humidity during the whole cycle of shipment. If the temperature exceeds acceptable limits, the system will automatically send notifications to your managers and the driver. Moreover, you can use IoT devices for monitoring the state of your assets, such as machinery, for example. All data collected from attached devices transmit to the internet automatically and can be accessed by ERP system users any time since it’s stored in the cloud. The use of IoT technology in the manufacturing sphere allows reducing human errors, reacting to harmful situations faster, and saving money on labor since your employees won’t have to perform time-consuming tasks manually.

Read Also How IoT Simplifies Our Life and in Which Spheres It is Used

Advanced Warehousing

Custom ERP systems can give you complete control over your warehouse. The use of QR codes and mobile scanning apps will simplify tracking inventory movement through the different areas of your warehouse and reduce the paperwork. After a new item arrives, an employee can scan it, and all the info will be automatically saved in the system. An item’s current state can be changed with a few clicks via the mobile application if needed. Drivers also can use this system for scanning QR codes to confirm that a particular item is loaded into the truck.

AI and machine learning technologies implemented in your ERP system can help analyze the flow of items through the warehouse to adapt your facility layout. For example, you can group materials in your warehouse according to their velocity. By putting fast-moving products closer to shipping lanes, you can reduce the time required for loading. The warehousing module for your custom manufacturing ERP system can help eliminate the waste of warehouse space and minimize the risk of losing track of a valuable item. Every movement from an item’s arrival at the facility to its shipping can be recorded with mobile QR scanning apps, reducing the likelihood of lost inventory.

Read Also Why ERP Software in Wholesale Distribution is not a Luxury But Already a Must

Workforce Monitoring

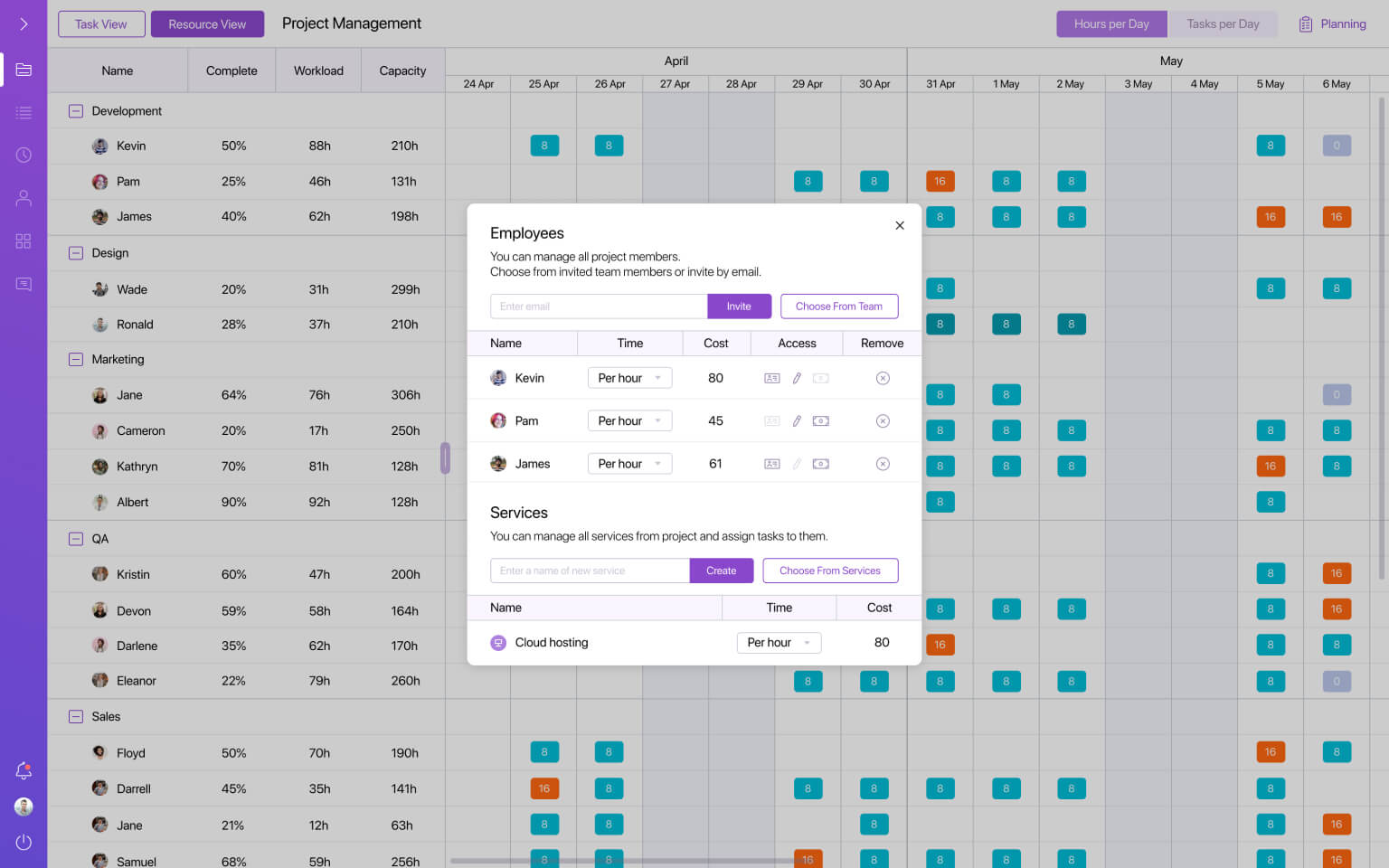

Screenshot from Project Management Application Based on the Gantt Chart Case Study

Screenshot from Project Management Application Based on the Gantt Chart Case Study

The workforce monitoring module allows tracking personal and team productivity. Managers can use it to set roles for various team members, assign tasks, monitor project progress, and assess particular employees’ contributions. Advanced resource planning features allow setting the cost per hour for a resource and measuring time spent on a specific task. Using this data, your manufacturing ERP system can calculate the appropriate cost of a single task or a group of tasks. The workload monitoring helps company managers to find underperforming employees or those who have too many activities. With a couple of clicks, such employees can be reallocated.

Conclusions

Manufacturing companies of any size can benefit from adopting an ERP system. Thanks to the integrated modules, an ERP solution can be affordable for a small company, and rich functionality can cover large enterprises’ needs. Software vendors that offer off-the-shelf ERP systems design their solutions to meet an average manufacturing business’s requirements. That’s why, when you buy a ready-made ERP system, you may find that it lacks some features crucial for your specific company. On the other hand, custom software development companies spend the time to know your company better and provide software solutions designed to solve your business problems.

If you want to learn more about ERP solutions for the manufacturing sphere, please contact us.