The logistics network is the foundation of every business dealing with physical goods. Whether you manufacture high-precision measuring electronics or sell tennis balls, you want to ensure supply and demand are always fulfilled. Often, supply chains are very complex to manage “as a whole.” Tons of intermediaries and multiple involved indicators to monitor require fracturing significant things into smaller parts which simplifies the overall management and helps detect bottlenecks more efficiently.

Dividing complex supply chain processes into inbound and outbound logistics is a pretty intuitive way of improving your effectiveness by focusing on things that are easier to handle. Today, we’ll consider the difference between inbound and outbound logistics, their main challenges, and ways to overcome them.

What’s Inbound and Outbound Logistics

Inbound logistics is a primary process within the world of logistics that encompasses the activities of purchasing and coordinating the movement of materials, parts, and unfinished inventory from suppliers to manufacturing plants, assembly lines, and warehouses. The primary purpose of inbound logistics is to secure supplies for production and assembly, resulting in secured and stable sales. In a semiconductor industry, for example, inbound logistics ensures the availability of such raw materials as silicon, germanium, gallium arsenide, and indium phosphide.

Efficient management, in this case, implies taking care of all the operations from when an order is placed to the subsequent allocation of supplies across suppliers and to the meticulous delivery and transportation arrangements for receiving and storage. Inbound logistics management specialist’s responsibilities span a broad spectrum, from fostering and nurturing strong supplier relationships, efficiently accessing raw materials, and skillfully negotiating materials pricing to organizing delivery methods.

Outbound logistics, in its turn, connects companies directly with their clients and ensures the seamless flow of finished goods from the company’s warehouses into the consumers’ arms. It is responsible for ensuring timely deliveries of finished products to their destination.

Read Also Handling Cargo Trucking With a Few Taps. How Mobile Apps Change the Logistics Business

Outbound logistics management teams master their ability to handle two significant issues: safeguarding the finished goods and streamlining their accessibility. Here, the balance between company cost savings and consumer satisfaction becomes vital. Managers must ensure that products are always on the move, the clients receive their orders timely, and there’s no room for idle inventory. Here, transportation is one of the most crucial parts of the entire process.

Major Differences Between Inbound and Outbound Logistics

|

Inbound Logistics |

Outbound Logistics |

|

| Focus | Supply | Demand |

| Responsibility | Receiving | Delivering |

| Handling | Inward | Outward |

| Deals With | Resources and raw materials | Finished products |

| Involved Parties | Suppliers, vendors, and distributors | Distributors, wholesalers, retailers, and customers |

| Key Objectives | Collecting materials to make products | Fulfilling the customer demand |

| Processes | Sourcing, Materials management, Warehouse receiving, Inventory storage | Order, Packing, Shipping, Customer service |

Both inbound and outbound logistics serve as the bridge that connects multiple suppliers upstream with people that consume the final product downstream. Inbound logistics, however, focuses on the supply side, while its counterpart, outbound logistics, directs its gaze toward the demand side of the supply-demand equation.

As these two domains interlace, there’s a difference in their management worthy of notion. Third-party entities pretty often oversee the complexities of inbound logistics. In contrast, outbound logistics often fall under the direct purview of the company itself. The company management team must ensure the precise execution of the final steps in the supply chain and keep the clients happy.

Also, inbound logistics includes the management of a complex web of suppliers and intermediaries involving the movement of raw materials across various locations. In contrast, outbound logistics management is often more straightforward since it manually handles the shipping from the manufacturing facility or warehouse to the end-users embrace.

Benefits of Effective Inbound and Outbound Logistics Management

Streamlined production. Optimized inbound logistics management ensures a steady flow of raw materials, reducing production delays and enhancing efficiency. With some automation and AI/ML algorithms, the entire supply chain can operate as clockwork and warn management specialists about seasonal product demand growth, for example.

Reduced lead times. Efficient outbound logistics management facilitates timely order fulfillment, enabling swift delivery to customers. The easier and quicker you move goods through the supply chain, the more money and effort you can save.

Enhanced customer satisfaction. Faster deliveries and reliable order fulfillment lead to increased customer delight and brand loyalty.

Cost savings. An agile supply chain with efficient inbound and outbound logistics reduces warehousing costs and boosts profitability.

Competitive advantage. Businesses gain a competitive edge by outperforming competitors with speedy and reliable logistics operations.

Read Also Top 5 Supply Chain Management Software That Streamline and Upgrade Your Business Processes

Resilience and adaptability. An optimized supply chain shields businesses from disruptions and market volatility and fosters resilience.

Sustainability. Efficient inbound and outbound logistics enable responsible sourcing, eco-friendly delivery routes, and green operations.

Operational efficiency. Coordinated inbound and outbound logistics can minimize downtime and enhance overall operating efficiency.

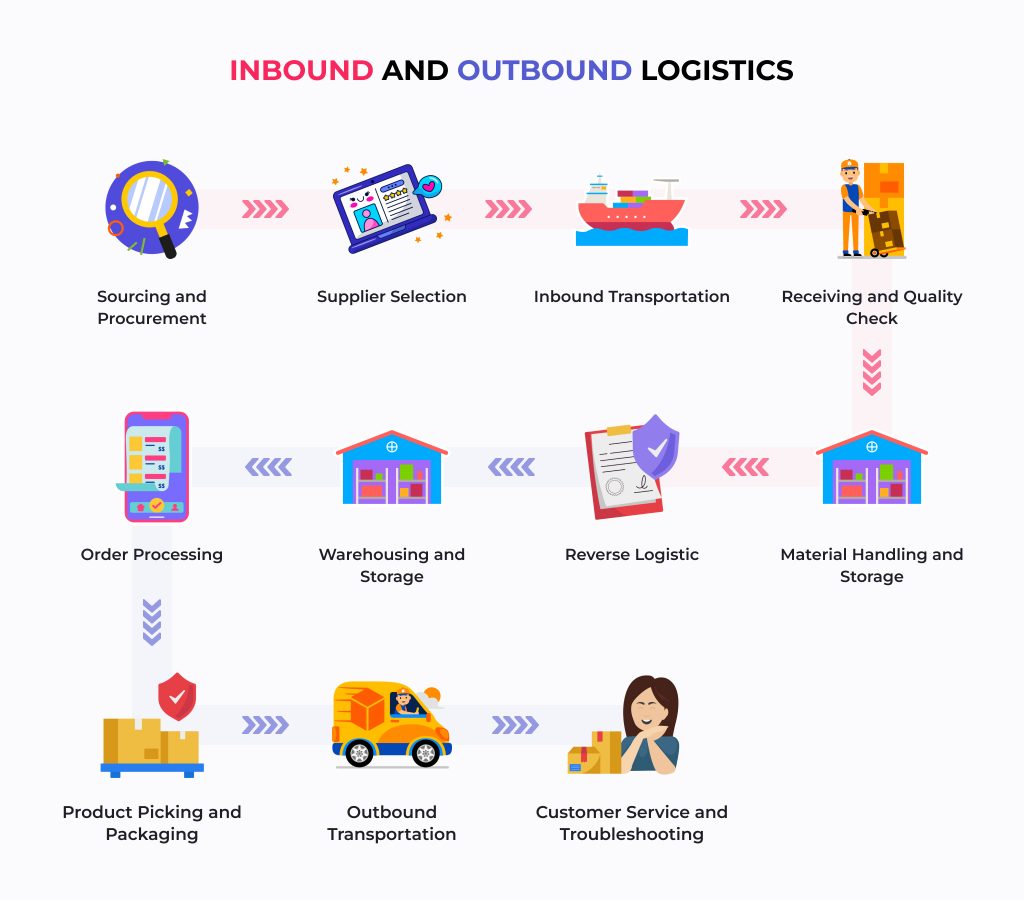

Operations Involved in Inbound and Outbound Logistics

Both inbound and outbound logistics operations are inseparable parts of a supply chain. They flow from one another, forming a smooth path where raw materials turn into goods ending up in the clients’ hands. Understanding all these aspects allows for more efficient logistics management and quick adjusting in case of unwanted delays.

Let’s start with the main stages of inbound logistics:

- Sourcing and Procurement. This operation involves identifying reliable suppliers capable of providing high-quality materials or products at competitive prices. As businesses seek to minimize costs and maintain product excellence, price negotiations, and smart procurement decisions are vital;

- Supplier Selection. Selecting suitable suppliers is a delicate process that requires balancing between trust, reliability, and cost-effectiveness. Inbound logistics management specialists scour the market for vendors who align with their quality standards, adhere to ethical practices, and demonstrate the agility to respond to fluctuations in demand;

- Inbound Transportation ensures the timely and secure movement of materials from suppliers to the receiving facility. Whether it’s leveraging advanced tracking technologies or optimizing shipment routes, a well-built inbound transportation system saves valuable time and resources, driving enhanced productivity;

- Receiving and Quality Check. Quality checks and inspections begin as the materials arrive at the receiving facility. Ensuring the delivered products and materials meet predefined standards is critical to avoid downstream disruptions. Meticulous inspection procedures prevent defective or subpar items from entering the supply chain, safeguarding brand reputation and customer satisfaction;

- Material Handling and Storage. Once the goods pass the quality tests, the focus shifts to efficient material handling and storage. It includes organizing, categorizing, and storing items within the warehouse, optimizing space utilization, and facilitating smooth retrieval processes. Automation technologies, such as robotic systems, can help reduce human errors and boost throughput;

- Reverse Logistic involves managing the return and disposal of materials, recycling or refurbishing where possible, and minimizing waste generation.

Read Also How to Build an Efficient Waste Management Application

Outbound logistics seems to be more straightforward and transparent. There’s no need to choose from many suppliers and organize numerous ways of supplying various materials from which the final product is made. However, the processes involved in outbound logistics management are vital and require due diligence:

- Warehousing and Storage. The vast and agile warehouse is one of the cornerstones of efficient logistics management. Modern warehousing techniques allow the processing of a plethora of different products with ease, thanks to intelligent organization and cutting-edge inventory management systems. Each item finds its place, poised for swift retrieval and dispatch upon receiving the call to embark on its journey;

- Order Processing. As customers tap the “Checkout” button, the automated gears of outbound logistics start to run. Real-time inventory data syncs seamlessly with advanced order management systems, enabling swift and precise order confirmations;

- Product Picking and Packaging. Warehouse workers, guided by sophisticated management algorithms, retrieve required items for each order;

- Outbound Transportation. After the packages are carefully sealed and labeled, the transportation process begins. Here, speed, reliability, and eco-consciousness take center stage. Businesses do their best to build the most optimal routes, leveraging advanced tracking technologies;

- Customer Service and Troubleshooting. For a customer-centric approach, resolving queries and addressing concerns efficiently is a must. A dedicated team of support experts must always be ready to ensure that every customer’s voice is heard and valued.

Common Inbound and Outbound Logistics Challenges And How to Overcome Them

Inbound Shipping Inefficiencies

Ensuring a steady influx of materials and products into warehouses can be hampered by inbound shipping inefficiencies. Delays in transit, missing documentation, and unpredictable weather conditions can disrupt schedules and jeopardize inventory availability. Since inbound logistics is often taken care of by third parties, the management team does not always have complete control over it.

Solution: Collaborative partnerships and real-time tracking forging robust partnerships with reliable carriers and freight forwarders can streamline inbound shipping. Implementing real-time tracking technologies enables logistics management teams to monitor shipments and foresee potential delays, allowing for timely adjustments and mitigating supply disruptions.

Source: Multi-Modal Transportation Management System

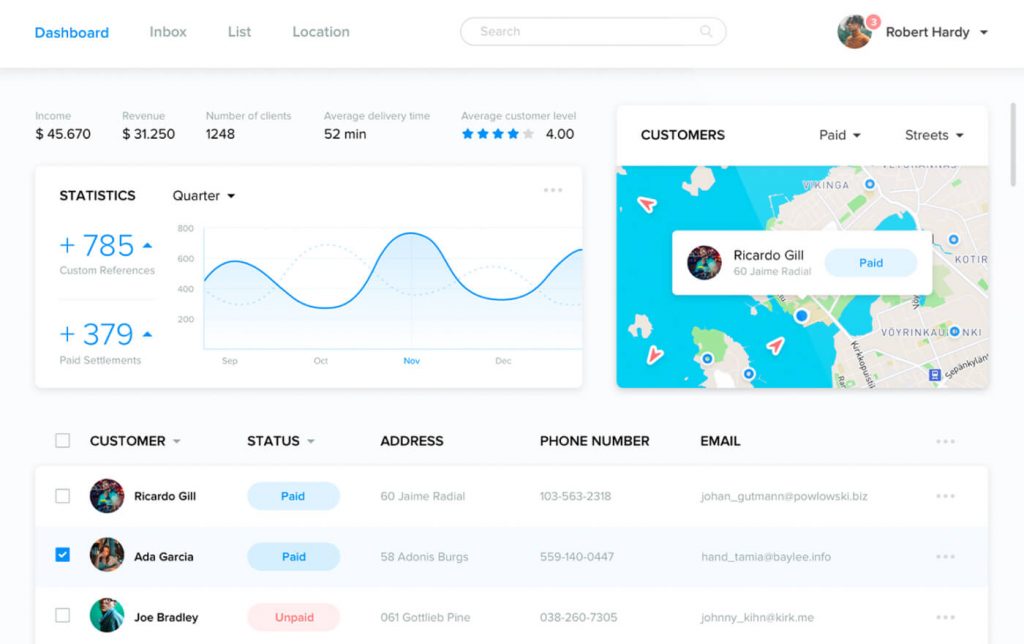

Balancing Supply and Demand

During peak seasons and special promotions, both inbound and outbound logistics face tremendous pressure, leading to bottlenecks in delivering and receiving goods. Rapidly changing economic conditions, pricing volatility, and many other factors can also harm the harmony between supply and demand. Poor logistics management practices and the absence of a proper planning solution may lead to warehouse yards clogged with vehicles causing confusion and delays.

Read Also What Yard Management Systems Are and How They Can Help Your Logistics Business

Solution: Here, data is your best ally. Logistics software solutions that provide demand forecasting functionality can help predict market trends and customer behavior accurately. Agile inventory management practices, including safety stock levels and just-in-time inventory, enable businesses to respond promptly to changing demand dynamics. Implementing a flexible workforce strategy, including temporary staff during peak times, ensures smoother deliveries and expedites order processing.

Source: Logistics and Supply Chain Management Application

Supplier Reliability

Heavy reliance on external suppliers exposes inbound logistics management to the risk of supplier delays, quality issues, and disruptions in the supply chain.

Solution: Diversification and risk mitigation by establishing relationships with multiple suppliers and geographically diverse sourcing options can enhance a company’s resilience. Conducting thorough supplier assessments and fostering open communication strengthens partnerships, ensuring a proactive approach to addressing potential issues.

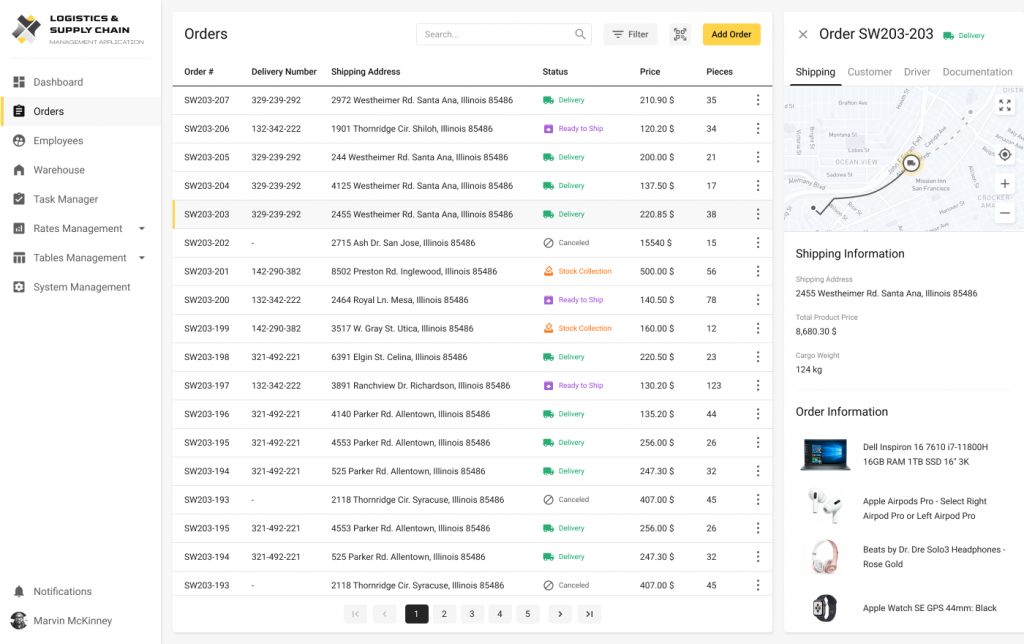

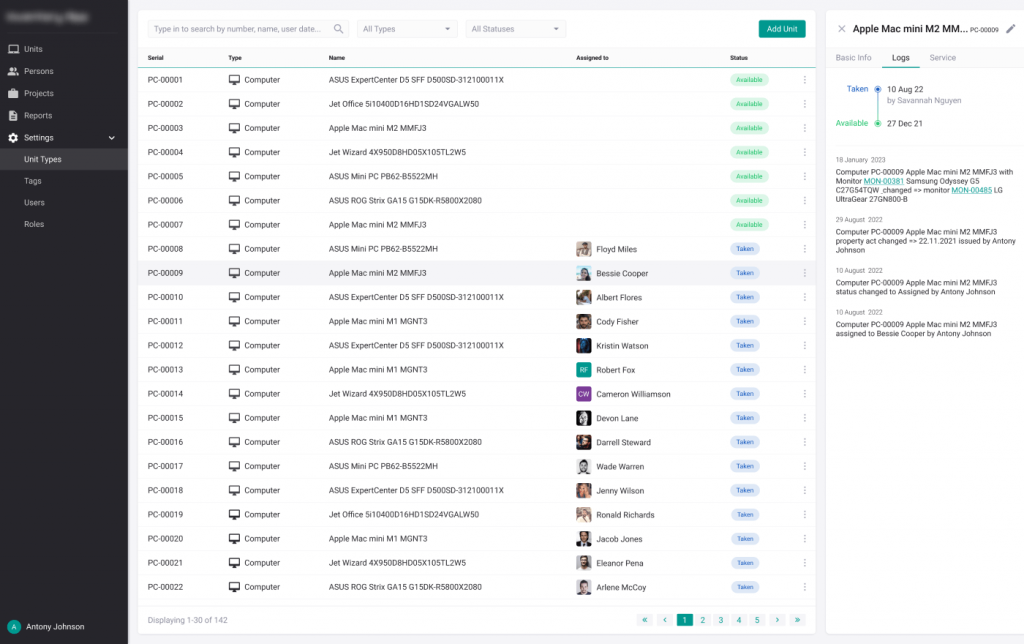

Coordinating Operations

With various stakeholders involved in inbound and outbound logistics, skillful coordination becomes crucial to avoid miscommunication and inefficiencies.

Solution: The logistics management team must have access to real-time monitoring software providing production, storage, and data distribution. It allows quick decisions on freeing more warehouse space or scaling shipping and delivery following the rise and fall in output. Centralized communication channels and integrated logistics management systems must invest in seamless coordination to enable real-time data sharing and streamline information flow across all parties, eliminating gaps in the supply chain.

Inventory Costs

Maintaining optimal inventory levels while managing carrying costs is a perpetual challenge faced by both inbound and outbound logistics management teams. As your business grows, you need more warehousing space and locations.

Solution: Inventory optimization and SKU (Stock Keeping Unit) rationalization help balance holding costs and inventory levels. Rationalizing SKU counts to focus on high-demand items reduces carrying costs and improves overall efficiency. Regular audits help avoid deadstock and ensure there’s room for valuable inventory.

Source: Warehouse and Inventory Management System

Transportation Costs

Escalating transportation costs can erode profit margins. It’s one of the most costly parts of logistics management.

Solution: Route optimization solutions rely on relatively simple technologies, such as GPS tracking, and use advanced algorithms to minimize transit distances and cut fuel costs. Also, reduced waiting times can speed up the shipment process, which increases customer satisfaction.

![]()

Source: GPS Vehicle Tracking System

Conclusions

Inbound and outbound logistics management are inextricably linked parts of a supply chain. They ensure that business has enough materials to produce finished products and possess all the means required for shipping them. In this case, efficient management includes more than constant monitoring of inventory levels and some vital KPIs. Another crucial element is maintaining due flexibility that allows businesses to scale following the fluctuations in supply and demand. If you struggle with overcoming one of the logistics management challenges described above or even some previously unknown ones, contact us, and we will deliver a software solution to help you deal with them in no time.