The ever-increasing pace of technological advances presents new challenges to all types of businesses, including manufacturing. Software solutions built using cutting-edge technologies enable manufacturers to improve their productivity and extract essential insights from the abundance of collected data. In this article, we’ll consider the main challenges that manufacturing companies face today and look at some possible solutions that modern software systems can provide.

Outdated Software

Yesterday’s best software solution, in most cases, won’t ensure your company’s competitive advantage tomorrow. There are plenty of medium to large manufacturing companies present on the market for many years that use applications adopted before modern comprehensive solutions were available. Such companies often rely on several apps that were not well integrated, and therefore their cost-efficiency leaves much to be desired. Unintuitive user interfaces, poor scalability, and tons of unstructured data generated by such apps are common obstacles on the way to straightforward workflow and effortless business processes automation.

Nowadays, many manufacturing companies find that their software solutions can’t meet their needs and satisfy customers’ ever-increasing demands. To achieve that, a company has to choose between two primary options. The first option is to bring new life into the existing software solution by modernizing it or building and integrating some new functional modules. Another option is to completely replace the current solution with a brand-new software system built using cutting-edge technologies. However, big manufacturing companies with large staff may fear that the slightest changes in the usual course of things will cause unwanted delays or require time-consuming retraining of employees. The reality is that using obsolete software solutions harms the manufacturing business the same way as using substandard materials or faulty machinery. That’s why close cooperation between a manufacturing company and a custom software developer may become necessary for anybody who wants to boost productivity and better adapt to rapidly changing business environments.

Read Also Application Modernization vs Building App from Scratch — Choosing the Lesser of Two Evils

Compliance With Regulations

As your manufacturing company grows and enters new markets, you will inevitably face the necessity to comply with many laws and regulations, both local and international. The need to follow dozens of new standards may affect all significant activities of your business, and you must prepare yourself beforehand. Standards related to security, finances, safety, workforce, and many other aspects are intended to create a conducive environment for manufacturing goods that are of excellent quality, safe for customers, and non-polluting. As you can imagine, different countries have different views on how this goal can be achieved, which leads to the variety of regulations even in countries with similar general standards.

All these regulations bring an additional complexity level for all the companies that produce goods and services for their customers. First of all, we talk about the documentation and the ways it must be stored and maintained. Also, the internal policies and procedures have to follow a series of prescriptions. All company activities such as product manufacturing, storing, and further delivery should be carried out following the regulations. Dealing with all these requirements without specially designed manufacturing software solutions may become an uphill task, especially for a company with many branches in different countries. Luckily, such a software solution as an ERP system can be a massive helper with all these issues. Such software can provide centralized access to the repository of compliance documents and standards, which can be pretty helpful for quickly adapting your business processes.

Read Also Strengthening Your Manufacturing Business With a Custom ERP Software

Shortage in Skilful Workers

Despite the undeniable progress in robotics and automation, manufacturing companies, especially the small ones, highly depend on human capabilities. One of the biggest threats for this sector of the economy is a looming labor shortage. The generation of baby boomers is facing retirement, while the younger generation, for the most part, does not see bright prospects in the field of production. Therefore, to overcome this problem, every manufacturing company should develop a more creative approach to recruiting new employees. Also, you must not underestimate regular training helping to improve the potential of the existing workforce.

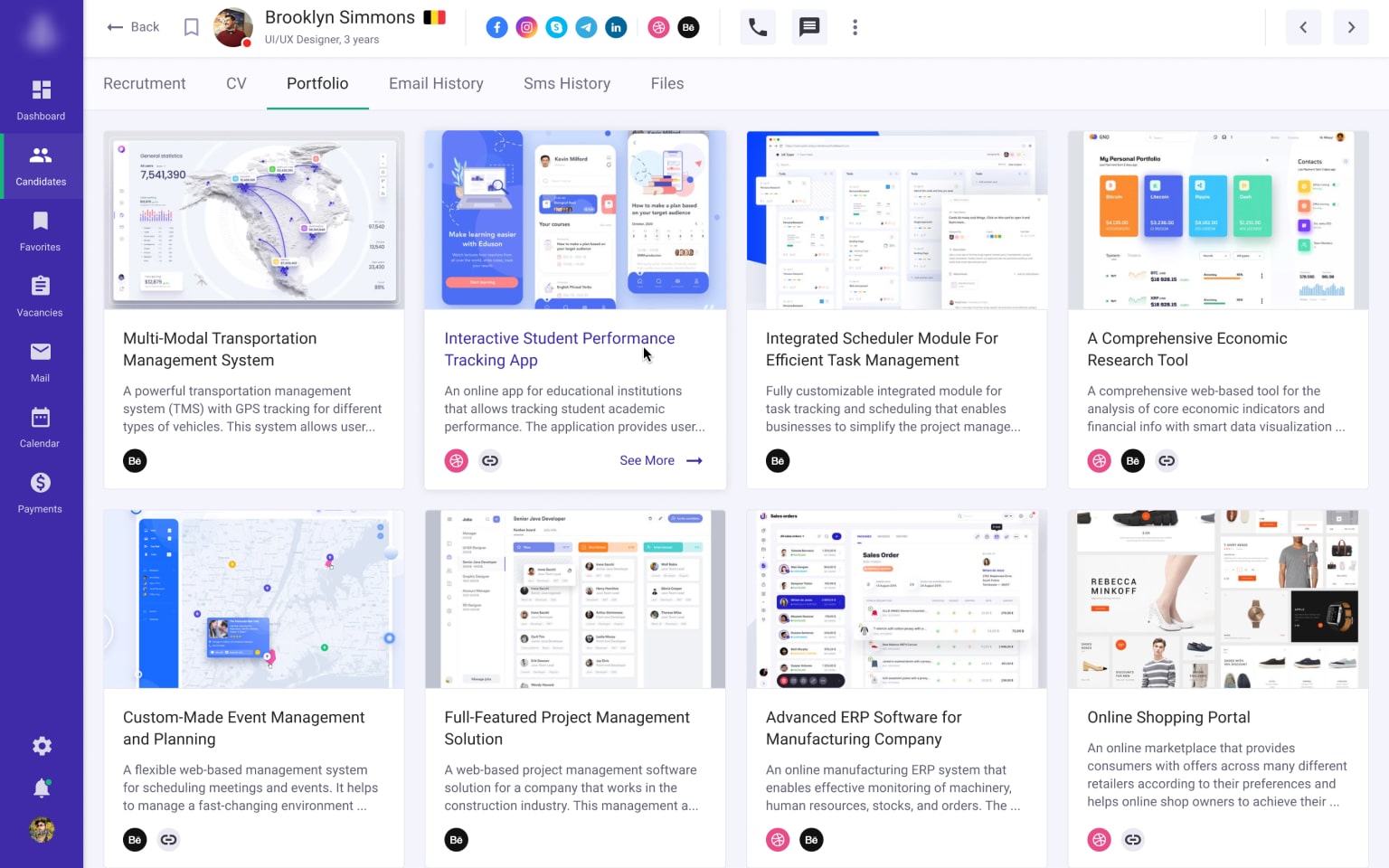

To overcome this problem, it’s essential to identify your talent gaps and plan a long-term hiring strategy. With an HR management system built according to your company’s needs, you can develop a talent development system that will help you find talented specialists, hire them, and maintain a high class of professionalism by regular in-house training. An intuitive web-based app can gather data from job search websites, analyze it and provide you with a list of promising specialists. The HRM system can help you search, find, and meet with potential hires or candidates, placing CVs or job opportunities. Our custom-made HR management system is an excellent example of such a solution:

Inventory Management

Inventory management and warehouse control are some of the most critical challenges every manufacturing company faces daily. The complexity is caused by the need to control the company’s employees, monitor the movement of goods and materials through the warehouse, and timely fulfill orders to keep the customers satisfied. Managing the stocks manually can be a very inefficient and time-consuming approach. Following this way, at some point, you’ll face multiple errors, inaccuracies, shortages, and other problems that can harm your business reputation.

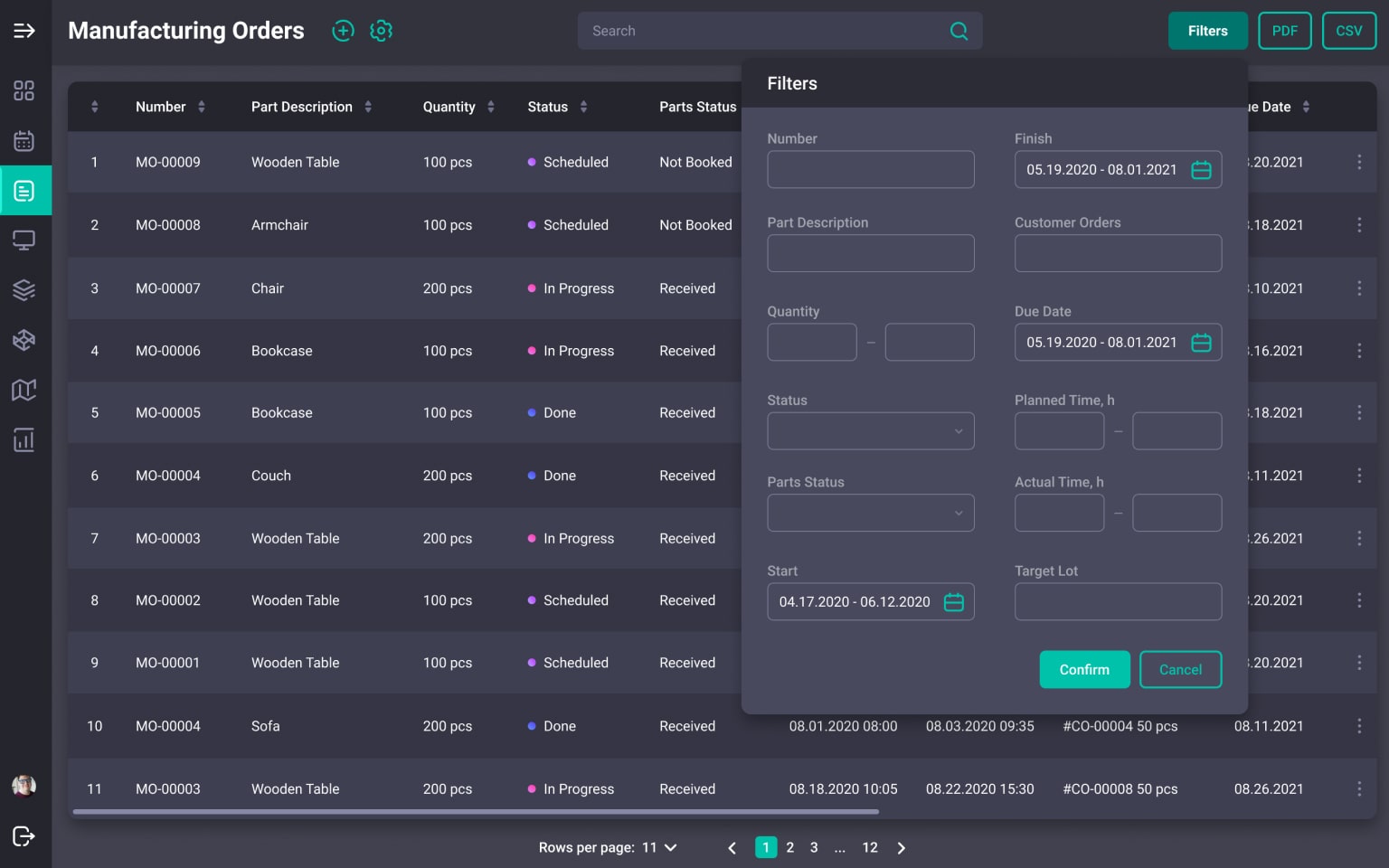

To overcome these potential problems, more and more businesses invest in ERP systems to help them achieve more control over their warehouses. Such software helps to automate inventory management and improve the control over all the manufacturing processes, from the flow of raw materials to the shipment of finished products. An ERP system built according to the needs of your business can timely remind you about the upcoming inventory audits that can help you find possible discrepancies between your records and the actual number of items in your warehouse. Built-in barcode scanners can significantly reduce the amount of required time and effort for such tasks. Also, EPR systems with built-in inventory management modules can help managers ensure that there are enough raw materials for manufacturing and all ordered goods are ready for shipment. Suppose you want to look at one of those solutions intended to boost manufacturing company productivity and improve its inventory management. In that case, you can check this custom-made ERP system that our developers have built for one of our customers in manufacturing domain:

Constantly Changing Consumer Trends

Customer interests change over time. Some decades ago, all you had to do was make an offer to help your potential customers save some money. Today, customers are pickier and may decide to prefer high-quality, ethically made products created by an environment-friendly company rather than focusing on more affordable options. These aspects, along with tough market competition, force manufacturing companies to perform regular market research to find their target customers and invest in custom CRM systems for achieving better customer satisfaction. Such software solutions won’t magically solve all your problems with the clients but will definitely make it easier for you to gain a competitive advantage on the market. Thanks to centralized access to all business-related data, you can quickly analyze the information gathered across your departments to develop powerful insights.

Conclusions

Nowadays, even if your manufacturing company doesn’t produce any innovative products, ignoring the latest technological developments may harm your business in the long run. Outdated software or lack of applications intended to improve your relationship with customers can weaken your position in the market and significantly complicate the process of retaining customers. Modern ERP systems for manufacturing, in their turn, allow boosting your business processes and help you to make data-driven decisions.

If you want to learn more about custom software for manufacturing companies and how it can improve your business, please contact us.