Manufacturing is nowadays one of the most large-scale and profitable sectors in the world. It is a complex process consisting of hundreds of workflows completely linked to each other. It’s like a pyramid where one block depends on another, and the coherent work of all layers is a key to overall success of the enterprise. But on the way to the bright future, the manufacturing companies face a plethora of challenges and have to look for workarounds to overcome them. And the entrepreneurs are constantly keeping an eye on the latest technology trends and evaluating their potential from the perspective of a particular manufacturing company. One of the most evident but meanwhile effective decisions contemporary companies make — is to embrace an up-to-date solution, such as cloud technology. Even superficial research may reveal the significant advantages cloud computing capabilities may provide, which makes business owners dig deeper and come to the conclusion that its implementation will help to optimize and facilitate the inner processes and therefore remain competitive. In this article we will shed light on the strongest points of cloud software development and the benefits it contributes to manufacturing business.

Main Benefits of Cloud Computing for Manufacturing

Centralized Data Storage

Just imagine the amount of data stored and processed within one big manufacturing company, especially if it previously had implemented the miracles of Industrial IoT. Sensors, the machinery equipped with, gather and exchange data, which requires storage space. On-premise servers in their turn, have the limited capability, which may no longer be enough for further data handling. Hypothetically, you may invest in purchasing another on-premise hardware. When it also runs out of storage space, nobody will get in your way to purchase the third one. Acquisition of additional servers could have been open-ended except for one thing — the cost. If you consider purchasing the high-performing on-premise hardware, its cost is prohibitive. And you should also take into consideration the costs and efforts for its further maintenance, which you will have to perform by your own strength and money. Unlike local servers, cloud can provide you with unlimited data storage space due to the existence of big amounts of data centers located across the globe for a comparatively lower price. Additionally, you are not binded to a concrete place, since essential data is available from anywhere, if you have a stable Internet connection of course.

Establish Processes for Output Optimization

Manufacturers strive to find the most efficient way to optimize the processes with the existing resources and meanwhile increase output. Which is quite logical, since the more elements you are capable to produce with the available resources, the more profit you will gain in the result. Of course, there is always an option to draw additional resources: human or monetary, but this way requires time, effort and obviously expenses. On the other hand, proceeding with existing resources optimization is cheaper and much faster. Another vital thing required to drive productivity is integration of various processes flowing within the company. Put it simply, end products production presupposes involvement of different processes and systems that operate separately and are not related to each other, but meanwhile have one common aim.

The use of cloud services will help to solve the issue with integration of unequal systems, but only in case the applications support this possibility. When systems are integrated and operate coherently, the inner workflows will be more streamlined. You will have a possibility to distribute the available resources and workload in a maximally rational way, which will have a positive impact on the total output.

Read Also Five Common Challenges For Manufacturing Industry and How Software Helps to Overcome Them

Streamlining the Supply Chain

Delivering the products to different corners of the world was and remains among critical points in manufacturing business. Supply chain involves separate organizations which are not connected to each other, therefore performing control over multiple partners scattered across the globe is almost impossible without proper software solutions.

Embracing cloud computing will be of great help to digitally connect the elements participating in your supply chain. Something like a web will be formed, where all the points are connected and their functioning can be monitored more easily. This approach will streamline the logistical processes and inventory management, and you will have a clearer picture of how the entire delivery process works. Additionally, weak points will be revealed (if any), which gives you a chance to improve them in a pointwise manner.

Real-time Monitoring

Will you rush into making decisions absolutely groundlessly, without any fundamental basis which in this case is data? Maybe, but only if you intentionally attempt to ruin your business and brand reputation. In any case, relying on gut feeling is not the best idea if it refers to your own company built from the ground. Much more reliable and secure way is to make vital decisions using firm relevant data. Cloud computing is a great tool for gathering and providing users with the real-time data collected from various systems integrated with each other. This approach will be of great help in case you intend to make more data-driven decisions. For example, you will have a clear vision of available stocks and machinery conditions, which will allow to take necessary measures promptly. In the result, you will not be caught unawares by unexpected equipment malfunctions or raw materials shortage.

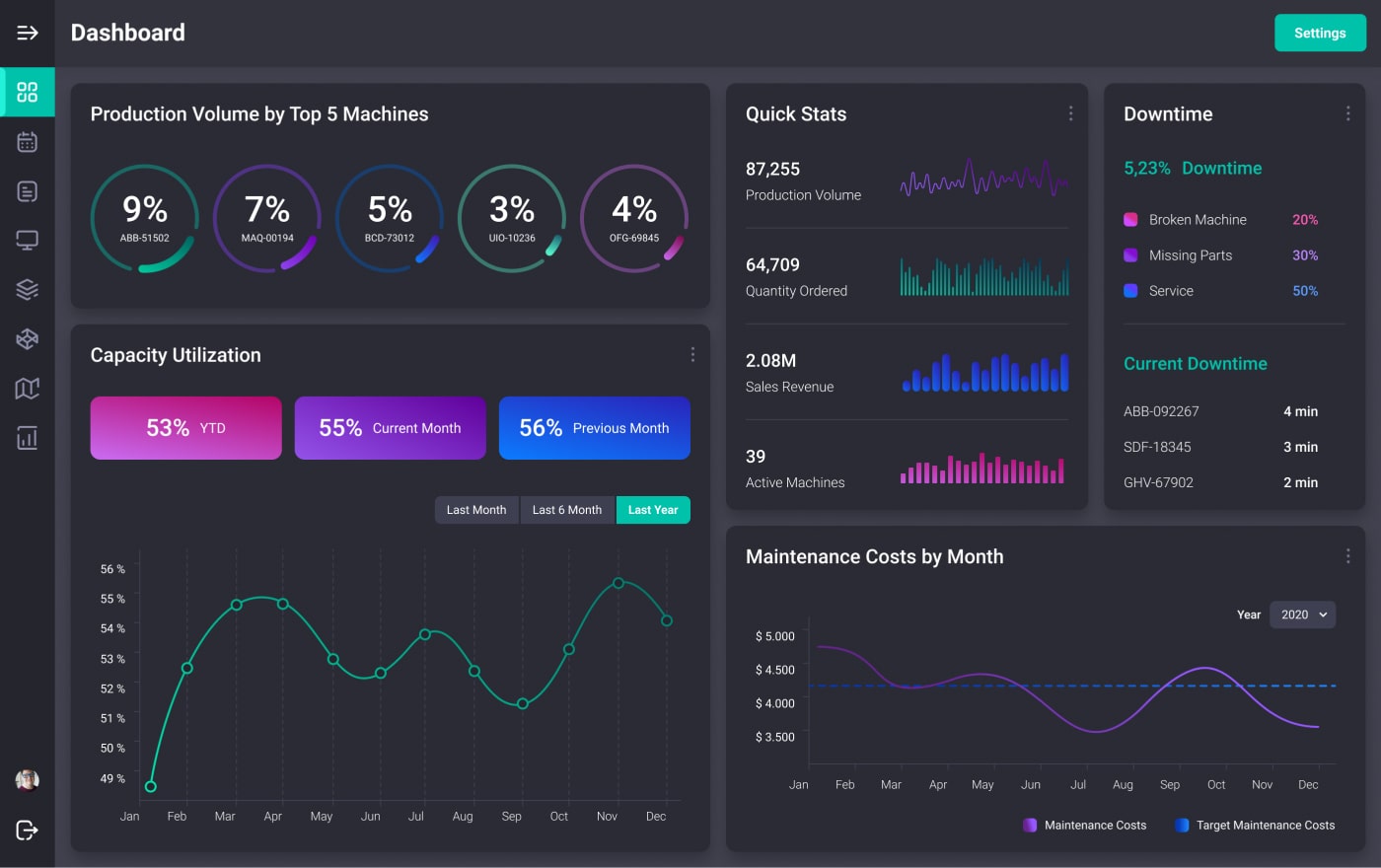

Screenshot from Advanced ERP Software for Manufacturing Company Case Study

Customer Satisfaction Increase

A manufacturing company may have a long way to success, which could have taken years or even decades. Along with company growth, development of digital solutions took place, and customers’ demands and expectations also changed, obviously not downwards. But systems, a manufacturing company had adopted in the beginning of the way, become outdated across the years. And in many cases the use of obsolete systems can do more harm than good if we consider the customer satisfaction. Possible downtimes due to the slow system functioning, machinery failures, poor warehouse management lead to the worse customer experience and therefore money losses. These undesirable consequences may be avoided through the adoption of more contemporary technologies such as cloud that would ensure stability of company functioning.

Read Also Strengthening Your Manufacturing Business With a Custom ERP Software

Conclusions

To keep the pace and remain competitive, companies operating in different spheres have to constantly look for new solutions. Cloud computing can provide a plethora of benefits to manufacturing companies, which outweigh the disadvantages. Cloud platforms may be of great help in streamlining the processes, output optimization, establishing better connections with suppliers and many more.

If you are currently looking for the best cloud solution for your manufacturing business and have no idea where to start, please contact us, our experts will provide you with the consultation considering the cloud solution that would suit you best.